Separation and filtration of gas

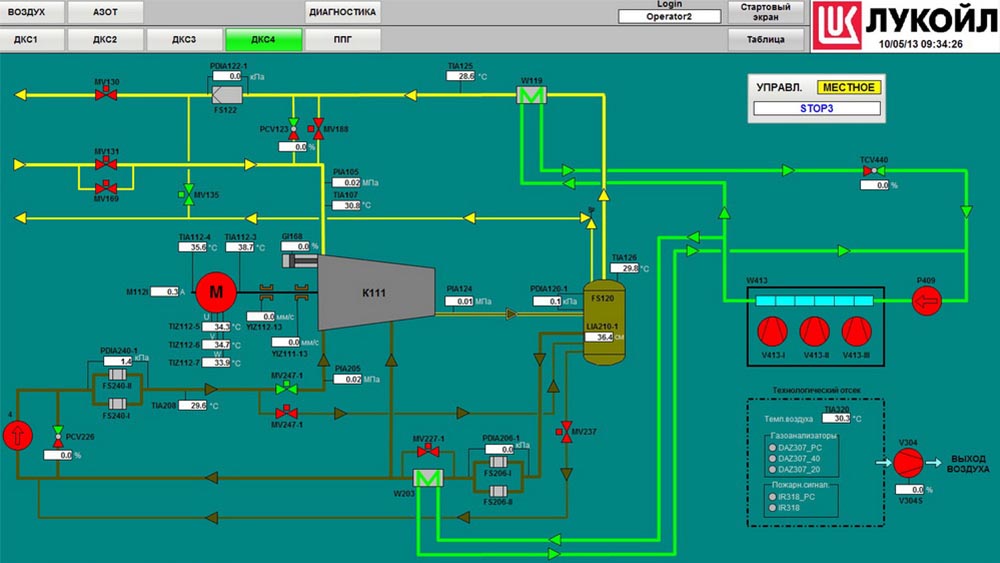

ACS of gas facility and gas feeding

Gas metering stations (autonomous)

Gas cooling equipment

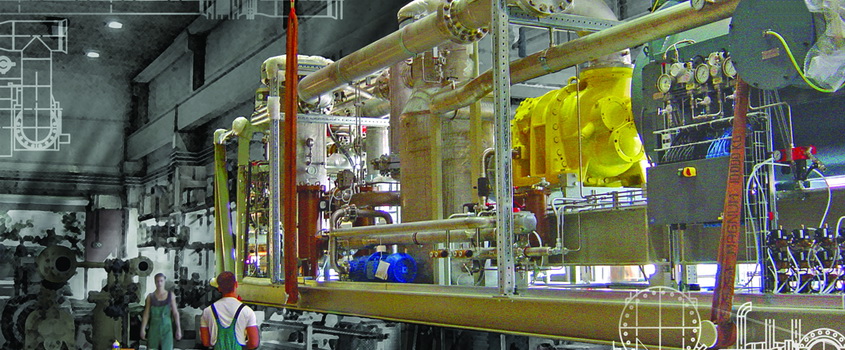

Systems for associated gas complex treatment

Associated gas treatment units

Booster compressor stations for associated gas

Gas drying modules

Safety systems

Gas metering units (integrable)

Packaged boilers

Systems for natural gas complex treatment

Block-type gas treatment units

Booster compressor stations of fuel gas for turbines

Multiunit gas treatment stations

Gas heating units

Gas parameters measuring

Heat-exchange units

Multimodule gas treatment units

Vacuum compressor stations

Fuel and starting gas treatment systems

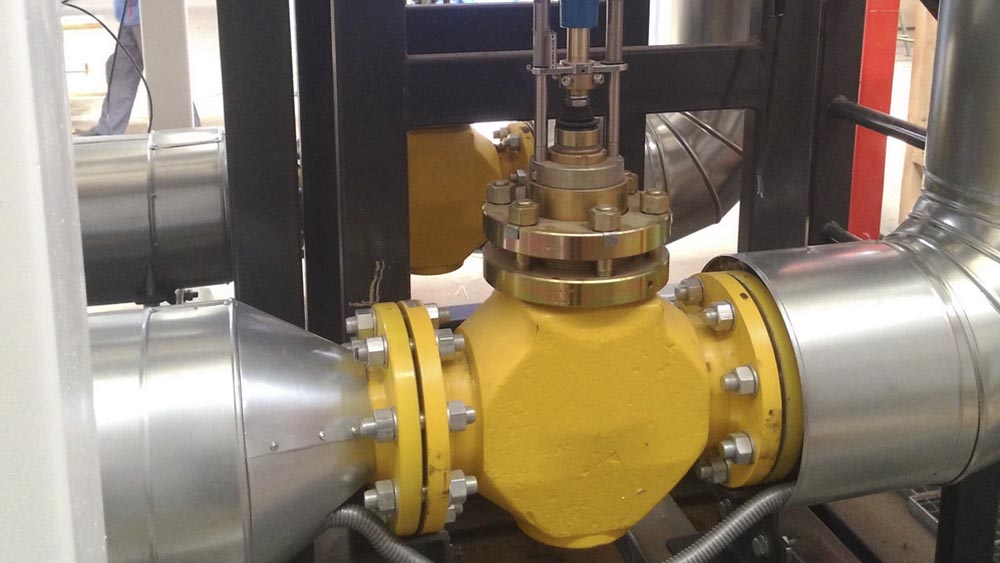

Reduction systems

Measuring of equipment characteristics

Small gas compressor units

Automated gas distribution stations

Specialized gas feeding equipment

Spare parts and consumables

Air compressor stations

Block-type gas-control stations