Upgrade and repair

In the course of long-term operation of gas treatment and compression units, there may be a need for technical re-equipment or repair of equipment.

In the ENERGAS Group these tasks are concertedly solved by the specialists of the design department, the service department and the repair department.

The reasons for upgrade may be:

- depletion of equipment life;

- change in the characteristics of the gas inlet pipeline;

- connection of new gas sources;

- significant change in the parameters and operating mode of coupled aggregates;

- connection of additional gas-consuming equipment;

- recommissioning after long-term shutdown ("cold standby").

When developing re-equipment projects, special attention is paid to the compactness of the additional equipment, maximum compatibility of the embedded elements, minimization of the work period in order to ensure the continuous operation of the head facility.

Depending on the upgrade target, we perform a number of tasks:

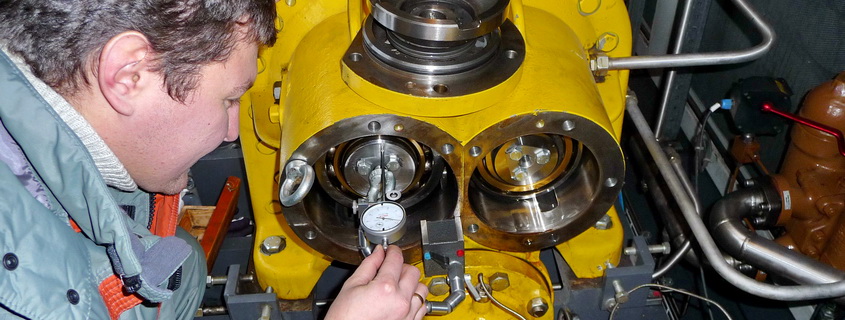

- control and auditing work;

- development of original engineering solutions;

- inclusion in the existing process flow diagram of additional assemblies and components;

- designing a new process flow diagram that meets the set goals;

- replacement or re-equipment of obsoleted elements and systems;

- supply and commissioning of additional package gas treatment units - when implementing large-scale projects.

Upgrade can be carried out on the site of the operator company or on the production and repair base of the ENERGAS Group - in the event of a large volume and complexity of activities.

Upon completion of the works, ServicENERGAS specialists perform pre-start procedures: adjusting, own tests, integrated testing within the facility (if necessary), training of the customer's personnel to the rules and norms of operation of the upgraded equipment.

As a result, upgrade provides:

- increase the service life of equipment;

- expanding the range of functionality;

- gas compliance at the outlet to the new design properties for purity, temperature and pressure;

- increase or decrease (depending on customer requirements) of the capacity resource - outside the initially set range;

- improving the level of reliability and safety;

- optimization of operating costs.

Gas treatment and gas feeding units of "ENERGAS" have a high level of maintainability in difficult climatic conditions, including extreme conditions. This makes it possible to carry out works all the year round and promptly.

The presence of the repair service and the repair shop within the ENERGAS Group allows for the qualitative execution of the relevant projects at the units of other manufacturers and suppliers. We carry out current (local) maintenance or overhauls with dismantling, transportation and back mounting of equipment.

If necessary, we supply original spare parts, components and consumables.

As a result of the repair, a detailed technical report is drawn up with the display and visualization of all stages. At the request of the customer, the progress of work can be recorded on video.