After 3 years of trouble-free operation as a part of the GTU-TPP of Kastamonu Plant, the gas-compressor unit underwent comprehensive maintenance

26 May 2018

Since 2014, in the special economic zone of Alabuga (Republic of Tatarstan) there is operating the Kastamonu Plant – Europe's largest enterprise for the production of laminate flooring and wood panels MDF / HDF.Own electric power for production needs is produced by a gas turbine unit with an installed capacity of 25 MW, created on the basis of the gas turbine of type LM2500+G4 DLE (GE).

The factory GTU-TPP includes a waste heat boiler, the heat capacity of which is also used to provide process procedures. At the site of autonomous power plant, there is operates boiler house for output additional amounts of heat. Fuel for the power supply complex is natural gas.

For this project, ENERGAS supplied and commissioned gas treatment and gas supply equipment: booster compressor unit (CU), block-type gas treatment unit, reduction unit.

CU compresses the gas to 3.8 MPa and feeds it to the power plant turbine. The unit is housed in a separate all-weather shelter; equipped with a two-level capacity control system and an automated control system with data transfer function on the top level of APCS. The gas consumption of CU is 12,000 m3 / h.

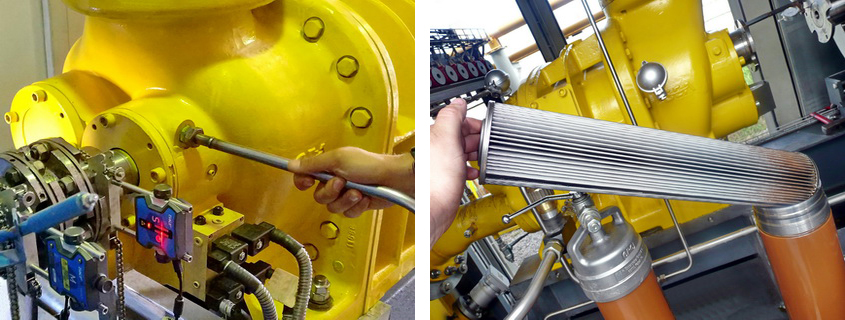

After 3 years of trouble-free operation (run time is more than 20,000 hours), the compressor unit underwent comprehensive maintenance. Scheduled tasks were carried out by engineers of the ServicENERGAS LLC (companies group ENERGAS).

In the course of maintenance the following works there were performed:

- Replacement of consumables (gas and oil filters, oil in the bearings of the motor);

- Check the alignment of rotating units (compressor and motor);

- Gaps measure and checking the status of the internal components of the compressor;

- Adjustment and calibration of position sensors and positioning of valves and hydraulic controllers;

- Functional tests of the oil system and cooling system of the compressor unit;

- Verification of operational parameters and their adjustment;

- Troubleshooting, drafting recommendations on components replacement.

Maintenance results are confirmed in the technical report of performed maintenance service.

REFERENCE. SEZ Alabuga is Russia's largest special economic zone of industrial type. It is created on December 21, 2005 on the territory of Tatarstan (Elabuga district), 210 km from Kazan. More than 30 Russian and foreign investors are implementing own projects here.

REFERENCE. Kastamonu Entegre is a leader in the forest products sector in Turkey and one of the ten largest companies in Europe for the production of MDF. Construction of a new plant in the SEZ Alabuga is one of the most ambitious projects of the company.

| Previous news | Back to the list | Next news |