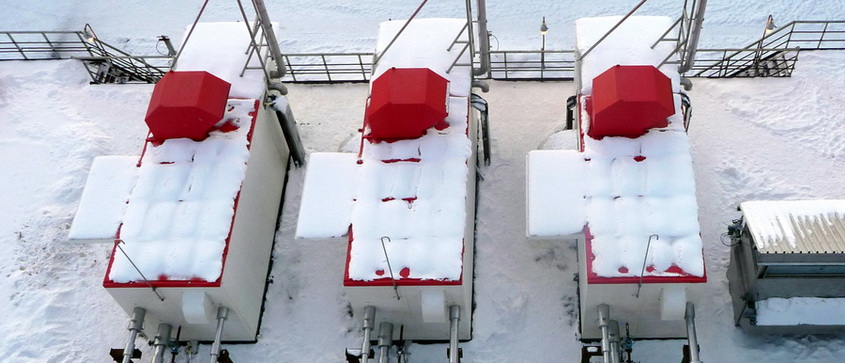

Associated gas compressor station at the Varandey field – 10 years of reliable operation in the conditions of the Far North

29 July 2022

The station consists of three gas booster units of low pressure and is involved in the transportation of low-pressure APG.

The compressor station (CS) has been operating at the site of the Oil Treatment Plant (OTP) of Varandey field since 2012. Operation mode of the CS as part of the facility of oil and gas production complex is uninterrupted with scheduled shutdowns for maintenance. The station was supplied and commissioned by ENERGAS.

This process equipment is designed to transport associated gas incoming from the end oil separation stage of OTP. The CS carries out additional purification and compression of low-pressure APG and ensures its injection under pressure of 0.5 MPa into the transport pipeline.

The station consists of three booster compressor units (CU) made based on screw oil-filled compressors. The volume capacity of each machine amounts to 450 m3 / h; gas flow rate is controlled by a special two-tier regulation system.

The specified parameters for the pumpable gas in terms of purity are guaranteed by the multistage filtration system of CU: protective strainer, inlet filter-scrubber of the 1st stage of purification, gas-oil separator of the 2nd stage and coalescing safety filter of the 3rd stage.

The delivery lines of units are equipped with a heat exchangers (with a built-in separator and a condensate collector), which cool the compressed associated gas and remove the resulting moisture. As a result, the calculated temperature of the working medium set by the design requirements is reached, the dew point is decreased and condensation during APG transportation is excluded.

One of the features of the project is almost zero gas pressure at the suction (0 ... 0.01 MPa g), that was taken into account at the design and production stages. In particular, the machines are equipped with system of quick-acting valves, which allows you to promptly cut off the intake pipeline from the mainline and thereby prevents the so-called back draft (release of oil from the oil system into inlet filter-scrubber).

The problems accompanying compression of high-density APG, which comes from OTP, were solved by increasing the oil and gas operating temperatures in the units, as well as due to applying a lubricant with higher viscosity and high resistance to saturation with heavy hydrocarbons.

Low-pressure CUs were specially devised for operation in the conditions of the Arctic, taking into account the remoteness and inaccessibility of the Varandey field. Special alloys and anti-corrosion materials were used in the equipment manufacturing, it was performed redundancy of some components and assemblies.

Modular compressor units are placed in compact enclosures of a block-container type, are fully automated, and equipped with life support systems (heating, ventilation, and lighting) and safety systems (fire detection and fire extinguishing, gas detection, alarm).

REFERENCE:

The Varandey oil field is located in the Nenets Autonomous Area, north of the Arctic Circle, in close proximity to the coastline of the Barents Sea. It belongs to the Timano-Pechora oil and gas province; in terms of reserves, it is classified as large. The first well was drilled here in 1974, and in 1985, the first tanker with industrial oil of Varandey was sent to Arkhangelsk. The field is developed by LLC LUKOIL-Komi.

Varandey Oil Treatment Plant is designed for dehydration and desalting of oil coming from Varandey, Toravay, Toboy, Myedsey, Perevoznoye and other fields in order to obtain marketable oil of the first quality group. In addition, here there is performed the processing of substandard oil returned from offshore tank farm (OTF) and coming from the terminal facilities of the oil pipeline Yuzhnoye Khylchuyu CPF – Varandey OTF.

| Previous news | Back to the list | Next news |