Maintenance during the warranty period

For reliable operation of process equipment there is required its timely maintenance. Scheduled regular maintenance prevents unauthorized shutdowns, ensures full life depletion of gas treatment and compressing equipment, as well as reduces the process costs of the operating company in general.

The basic service program, operating in the warranty period, includes a set of activities:

- diagnostics of all components and systems;

- operating tests;

- checking and adjusting of the operational parameters;

- replacement of spare parts and consumables;

- troubleshooting;

- development of recommendations for the customer on the basis of routine maintenance work.

We also solve the operational technical issues in clock round mode (24/7) and advise the representatives of the operator company.

Comprehensive maintenance of the equipment is punctually performed in accordance with the schedule coordinated with the customer - as a rule, every 4,000 operating hours. On average, over the year, our specialists make over 50 scheduled trips to various sites, including remote or hard-to-reach (the Far North, Siberia, the Far East, etc.).

Units of ENERGAS are designed according to special (individual) projects, in various versions of the completing and configuration - on the basis of the customer's requirements and operating features at a specific facility. These factors are taken into account when planning and organizing the maintenance of the supplied equipment.

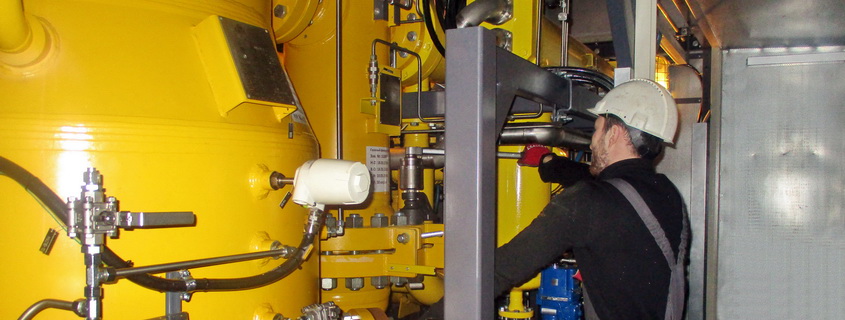

In particular, within the block-modules there is a free space for quick and comfortable access to all assemblies and elements, which provides the possibility of an all-season high-quality maintenance in any climatic conditions, including extreme.