Factory of JSC Systemic Aluminum in Krymsk is equipped with its own power supply complex

14 November 2018

Industrial enterprises are still dependent on energy supply problems. Among them, there is a restriction of capacity from local power networks, overestimated tariffs, and insufficient level of reliability of power supply. All together, this leads to unacceptable operational costs and the loss of competitiveness.Prudent and far-sighted industrialists, especially in energy-intensive industries, increasingly achieve the energy efficiency of their enterprises, growth in profitability of production and competitiveness of products through the creation of autonomous power supply complexes.

Confirmation of this is factory for aluminum extrusion production (JSC Systemic Aluminum), which located in Krymsk of Krasnodar Territory. This autumn, the enterprise is equipped with its own power supply center – gas turbine power plant (GTPP) with installed capacity of 4.7 MW.

The new facility will provide electrical power for production capacity of the factory. It is planned that the electricity generated here will be significantly cheaper than the market. The GTPP for own needs is based on Taurus 60 turbine manufactured by the Solar Turbines Inc.

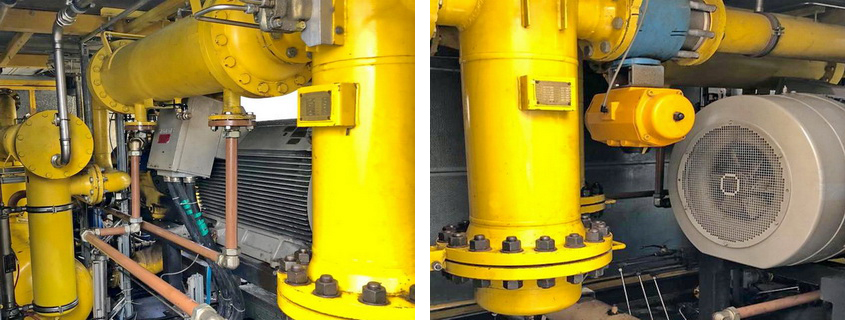

Launch of power supply complex became possible due to the commissioning of the Enerproject compressor station (CS). The CS of type EGS-S-150/335WA with rated capacity of 4,236 m3 / h is designed for compression and supply of fuel gas under pressure of 1.5 MPa (g) into gas-turbine power generating unit.

Previously, this CS was operated in France, and then was in long-term storage. After movement to other facility, the unit was reconstructed taking into account the changed operating conditions. This task was solved by service specialists of ENERGAS Group – the official partner of the Swiss company Enerproject SA in Russia.

At the first stage, a technical audit of compressor, process and electrical equipment was carried out; the input and output pipelines were inspected; the scope of work was determined, and the schedule for their implementation was agreed upon.

At the second stage, engineers of ServicENERGAS LLC have conducted restoration work with replacement of consumables and defective parts. There was installed new software, connected and configured automated control system of CS. Local ACS is integrated with the upper level of the APCS of the gas turbine power plant.

There were added new set points and protections. CS underwent pressure testing with nitrogen for the checking all assemblies and joints for tightness. There was performed set of start-up and adjustment works.

Reconstruction and adjusting were completed with own (individual) tests and a 72-hour comprehensive testing as a part of the GTPP. There has been checked the operability of all the components and systems. The compressor station has operated in a routine mode, without any complaints. Under the terms of the contract, the project was implemented as soon as possible.

| Previous news | Back to the list | Next news |