Specialists of the company "ServicENERGAS" carried out a technical audit of the vacuum compressor station for the needs of JSC Gazpromneft-NNG

5 January 2018

The vacuum compressor station (VCS) was delivered in 2012 by ENERGAS as part of equipping the facilities of JSC Gazpromneft-Noyabrskneftegas located in the Purovsky district of the Yamal-Nenets Autonomous Area, with equipment for compressing low-pressure associated gas.

It was planned that the VCS will operate as part of the booster pump stations No.2 (BPS-2) of the Yarainer field. However, the implementation of the project was suspended, and the unit was transferred to long-term storage.

Under the decision of Gazpromneft-NNG, the VCS is withdrawn from the conservation mode for operation at the preliminary water removal unit (site of the BPS-2) in the Vyngapur field, where it will form the basis of a system for recovery of associated petroleum gas of low separation stages.

The whole cycle of pre-starting works, including supervision, commissioning, own tests and testing of the operability of the VCS within the facility, will be performed by LLC ServicENERGAS (ENERGAS Group).

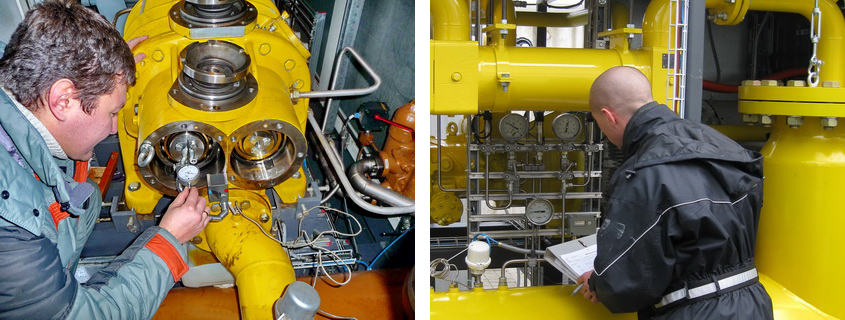

At present, service specialists conducted control-and-audit works. As a result of the technical audit, a defect sheet was prepared for the planning and subsequent carrying out of local repair of gas-pressure equipment.

In accordance with the new project, VCS is designed to compress low-pressure (0.001 MPa) APG of the end stage and its feeding, after combining with gas of the first separation stage, to the existing main compressor station.

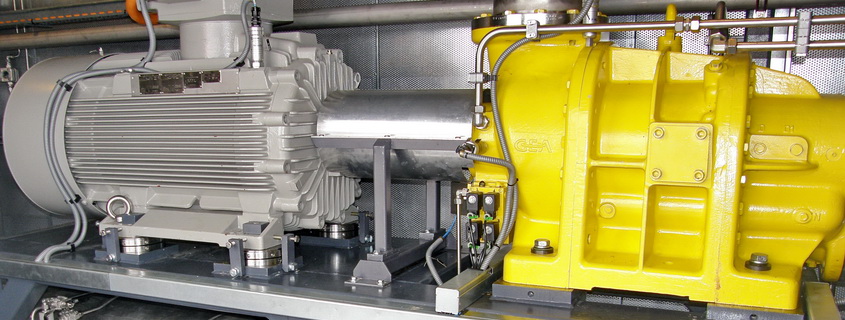

Vacuum CS is made on the basis of oil-filled screw-type compressor. The gas treatment at the compressor inlet is performed by a highly efficient two-stage filter-scrubber (with a system of automatic drainage) integrated in the process unit's block-module.

The rated capacity of the unit is 1,500 m3 / h; gas flow is controlled by a special two-level control system.

The equipment is designed taking into account extreme operating conditions (minimum air temperature - minus 59°C, average temperature of the coldest five-day period - minus 50.5°C). VCS is housed in its own all-weather shelter, equipped with all necessary life support and safety systems and will operate in an automatic mode. Local ACS is integrated with the upper level of APCS of BPS-2.

REFERENCE. Previously, ENERGAS Group supplied and commissioned vacuum compressor stations at a number of facilities of JSC Gazpromneft-NNG. This is BPS-1 and Central Production Facilities (CPF) of BPS-3 of Vyngapur field, Oil Processing and Pumping Shops (OPPS) of Vyngayakha and BPS-2 of the Ety-Pur field.

REFERENCE. Gazpromneft-Noyabrskneftegaz is engaged in oil and gas production activities in the Yamal-Nenets and Khanty-Mansi Autonomous Areas. Since the establishment of the enterprise, more than 850 million tons of hydrocarbons in oil equivalent have been extracted. Taking into account the branch of Gazpromneft-Muravlenko, the company develops 28 fields.

| Previous news | Back to the list | Next news |