The system for recovery of APG of low separation stages was put into operation at the site of CPF BPS-3 of Vyngapur field

30 April 2013

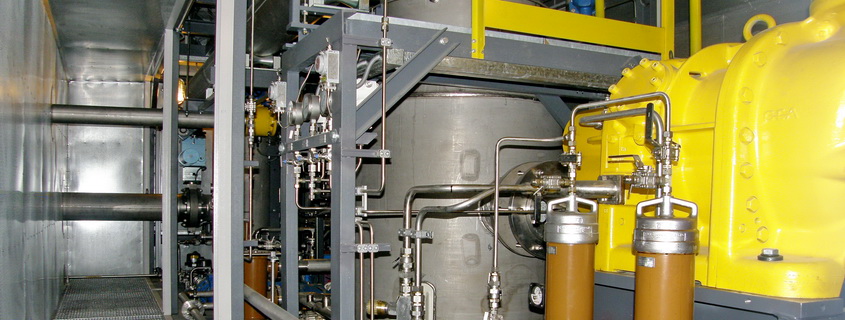

At the site of Central Production Facilities (CPF; the BPS-3 area) of Vyngapur field of JSC Gazpromneft-Noyabrskneftegas, there are successfully completed 72-hour comprehensive testing of a system for recovery of associated petroleum gas of low oil separation stages.It was also tested two ENERGAS vacuum compressor stations (VCS), which are the basis of this system. In the course of testing, the both VCS worked out in a routine mode, without any complaints. There has been checked the operability of process, compressor and electrical equipment and automated control systems.

VCSs perform compressing low-pressure (0.001 MPa) associated gas of the end stage. Compressed APG is injected into the gas transportation system under the pressure 0.7 MPa.

Vacuum CSs are made on the basis of oil-filled screw compressors. The rated capacity of the each unit is 4,000 m3 / h; gas flow is controlled by a special two-level regulation system. VCSs operate in an automatic mode. Local ACSs are integrated with the upper level of APCS of BPS-3.

There are several main issues that make low-pressure APG compression process complicated: need for additional associated gas purification; risk of condensate dropout inside the gas system; negative impact of very low inlet pressure close to the vacuum; changes of the gas composition; severe operating conditions.

Therefore, this technological task is solved by special projects – on the basis of a set of consistent engineering solutions.

In particular, the gas final purification at the compressor inlet is performed by a highly efficient two-stage filter-scrubber (with a system of automatic drainage) integrated in the process unit's block-module.

At the design stage, there were carried out a detailed analysis of the gas composition and calculations in special software that creates a theoretical model of the behavior of a gas under certain conditions (temperature and pressure). This made it possible to determine the optimal operating temperature parameters of oil and gas, for which compression processes runs out of the condensation zone.

In unit's oil system are used special lubricants with higher viscosity and high resistance to saturation from the heavy hydrocarbons.

Suction line is equipped with quick-acting valves with electric actuators and spring failsafe closing devices, that allows to cut off the compressor station gas circuit from the gas inlet pipeline.

VCSs were designed taking into account extreme operating conditions (minimum air temperature – minus 59°C, average temperature of the coldest five-day period – minus 50.5°C). Special alloys and anti-corrosion materials were used in the production. It was performed redundancy of some components and subassemblies of equipment.

Vacuum CSs are housed in its own all-weather enclosures; they are equipped with all necessary life support systems (heating, ventilation, and lighting) and safety systems (fire detection, gas detection, alarm, and fire fighting).

All the pre-start activities, including erection supervision, start-up and adjustment works, own and integrated testing of VCS were performed by the company ServicENERGAS (ENERGAS Group). The system for recovery of associated petroleum gas has been commissioned.

REFERENCE. Vyngapur oil and gas condensate field is located in the Purovsky District of the Yamal-Nenets Autonomous Area. It was discovered in 1968 and has been in commercial development since 1982. It has a well-developed infrastructure. It is one of the largest fields of JSC Gazpromneft-Noyabrskneftegaz and along with Sporyshevskoye, Kholmogorskoye and Chatylkinskoye fields provides the bulk of the company's production.

Gazpromneft-NNG is engaged in oil and gas production activities in the Yamal-Nenets and Khanty-Mansi Autonomous Areas. Since the establishment of the enterprise, more than 850 million tons of hydrocarbons in oil equivalent have been extracted. Taking into account the branch of Gazpromneft-Muravlenko, the company develops 28 fields.

| Previous news | Back to the list | Next news |