ServicENERGAS carried out comprehensive maintenance of associated gas treatment system at the West-Mogutlor field

4 April 2016

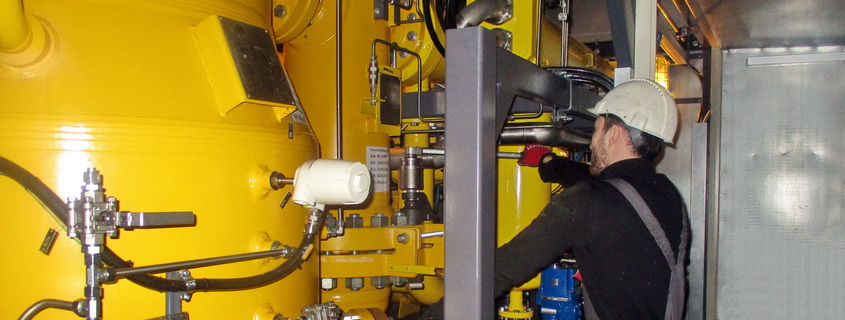

At the Main Transfer Pumping Station (MTPS) of West-Mogutlor oil field (OJSC Aganneftegasgeologia) there is operates associated gas treatment system (APG TS), supplied by the ENERGAS Company. It is a multifunctional process complex, it includes the following equipment:- booster compressor unit of screw type;

- adsorption gas dryer;

- gas cooling unit (chiller);

- gas metering station with flow meters.

ENERGAS experts developed this project on the basis of special engineering solutions, allowing to achieve negative dew point temperature on water (-20°C) while APG compression. Another feature is that dehydration of associated gas is carried out by two methods: refrigeration and adsorption.

All equipment is located at a single site, is placed in separate all-weather enclosures and fully automated. Operation mode as part of MTPS is continuous. APG TS sequentially performs the following process tasks:

- Dehydration – separating fractions from source associated gas which can dropout as condensate when temperature changes during the subsequent compression.

- APG second-stage treatment at gas inlet to the compressor unit. It is implemented by high efficiency separator – inlet filter-scrubber.

- Compression – increase of gas pressure to the projected level of 3 MPa required for injection of APG into the transport pipeline.

- Metering of treated gas amount.

- Cooling of associated gas up to the stable parameters, specified by design requirements.

From the date of commissioning of gas treatment system the operating time was counted more than 18,000 hours. Currently the equipment passed comprehensive maintenance. Scheduled tasks were carried out by engineers of the LLC ServicENERGAS (companies group ENERGAS). In the course of maintenance the following works there were performed:

- replacement of consumables of the compressor units and gas dryer as well as chiller;

- change of filtering elements of separation system;

- diagnosis of automated control system;

- correction of the gas flow meters;

- functional tests of the all utility systems;

- verification of operational parameters and their adjustment;

- troubleshooting, drafting recommendations on components replacement.

| Previous news | Back to the list | Next news |