The first overseas ENERGAS project turned 10 years old

8 August 2022

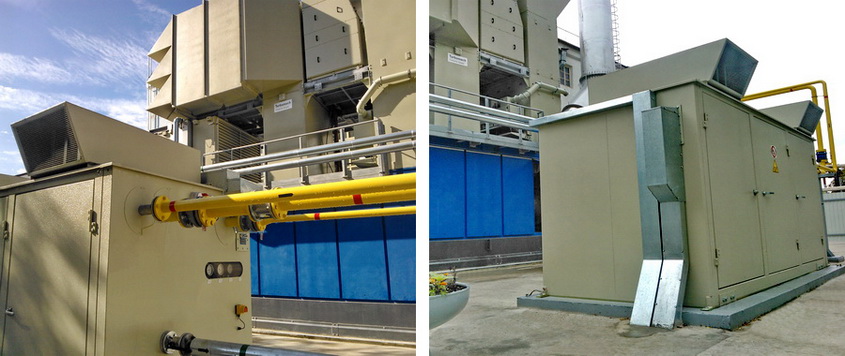

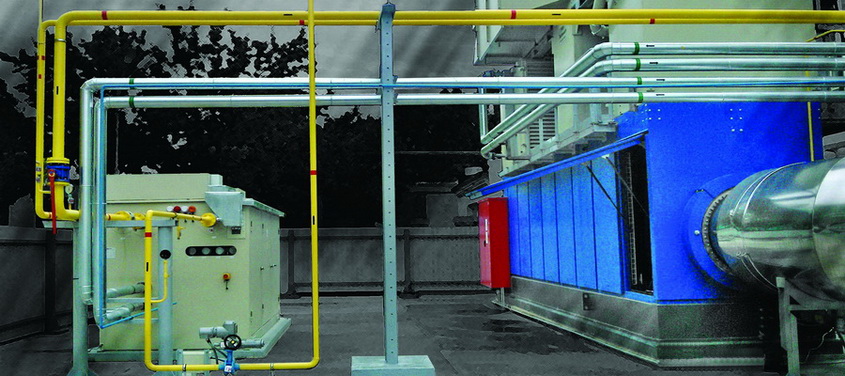

In August 2012, ENERGAS launched booster compressor station for the Turbomach TBM-C40 gas turbine unit (GTU) operating as part of the autonomous power supply complex of Minsk Combine of Silicate Products. This BCS feeds the GTU turbine with fuel with specified parameters in terms of purity, temperature, pressure and flow rate.

Among the priorities of the ENERGAS are production, launch and maintenance of gas treatment and compression units for generating facilities. Today, the ENERGAS process equipment provides high-quality fuel for 220 gas turbines and gas-reciprocating units with a total capacity of over 6.7 GW.

The commissioning of the BCS at the Minsk CSP was the company's first project carried out outside of Russia, as well as the first in the field of gas feeding to power supply complexes of industrial enterprises.

The compressor station with a volume capacity of 1,530 m3 / h is made based on screw oil-filled compressor. Gas flow rate depends on the load of the conjugated GTU and is controlled in the range from 0 to 100% of nominal. For control, a special two-tier capacity regulation system is applied.

The efficient compressor module of station gives a high gas compression ratio:

- Pressure at the suction is 0.3 MPa,

- Pressure at the delivery line is 2.5 MPa (limited by the settings of GTU).

The project requirements for the fuel purity are ensured by the multistage filtration system of BCS: inlet protective strainer, gas-oil separator of the 1st stage of purification and coalescing safety filter of the 2nd stage.

The process flow scheme provides for the stable maintenance of the calculated fuel temperature. The delivery line of the BCS is equipped with a heat exchanger which cools the working medium and guarantees the optimum temperature of gas supply to the turbine.

Modular compressor station is placed in compact enclosure of a block-container type, is fully automated, and equipped with life support and safety systems.

The Minsk Combine of Silicate Products has been in existence since the end of the 19th century (since 1895). At present, it is the largest producer of building and thermal insulation materials in the Republic of Belarus.

Intensive development of production and development of the production of modern products of European quality required the upgrade of the power supply system of the combine. The most profitable option was to equip the enterprise with its own power supply complex with the use of advanced technologies of gas power industry.

As a result, for 10 years now, the Swiss GTU Turbomach, based on the Centaur 40 GS turbine (Solar Turbines Inc.), has been effectively operating at the site of the steam-power workshop of the Minsk CSP. The installed capacity of the generating equipment is 3.5 MW.

The implementation of the project made it possible to derive a double benefit. Firstly, due to reduction of expenses for the fuel and energy component, the cost of manufactured products decreased, which increased the competitiveness of the combine. Secondly, the power supply complex not only completely supplies electricity to the CSP's own needs, but also allows the company to receive additional profit by selling surplus electricity to local power grids.

Let's summarize the story about the first overseas project of ENERGAS as follows. Over the past 10 years, the company has supplied more than 20 process units for gas treatment of various functional purposes to the Republic of Belarus alone. Thus, cooperation between ENERGAS and Belarusian colleagues continues to grow on a professional basis - in the interests of the development of the energy sector and the economy of the two countries.

Press office of the ENERGAS Companies Group

| Previous news | Back to the list | Next news |