At the PWRU BPS-2 of Vyngapur field, the own testing of vacuum compressor station of ENERGAS is completed

24 August 2018

At the Preliminary Water Removal Unit (the BPS-2 area) of Vyngapur field of JSC Gazpromneft-Noyabrskneftegas, there are completed adjustment and own testing of vacuum compressor station (VCS), supplied by ENERGAS Company.

Station is the basis of a system for recovery of associated petroleum gas of low oil separation stages. VCS is designed to compress low-pressure (0.001 MPa) APG of the end stage and its feeding, after combining with gas of the first separation stage, to the existing main compressor station.

In the course of individual test run, VCS was worked in a routine mode. Put into operation will take place after the 72-hour functional tests of equipment as a part of the facility of oil-and-gas production complex.

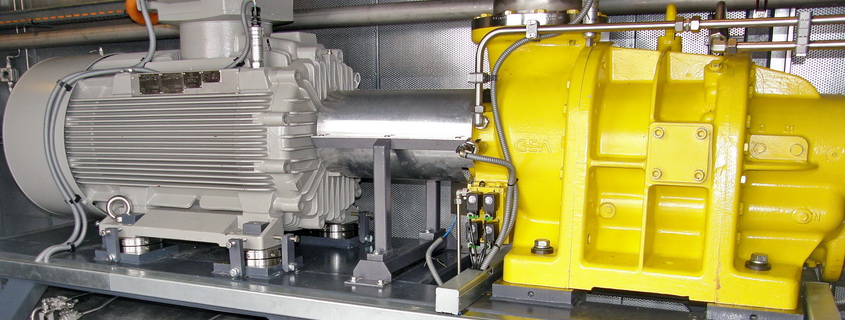

Vacuum CS is made on the basis of oil-filled screw-type compressor. The gas treatment at the compressor inlet is performed by a highly efficient two-stage filter-scrubber (with a system of automatic drainage) integrated in the process unit's block-module.

The rated capacity of the unit is 1,500 m3 / h, gas flow is controlled by a special two-level control system.

The equipment is designed taking into account extreme operating conditions (minimum air temperature - minus 59°C, average temperature of the coldest five-day period - minus 50.5°C). VCS is housed in its own all-weather shelter, equipped with all necessary life support and safety systems and will operate in an automatic mode. Local ACS is integrated with the upper level of APCS of BPS-2.

All the pre-start activities, including erection supervision, start-up and adjustment works, own and integrated testing of VCS are performed by the ServicENERGAS Company (ENERGAS Group).

| Previous news | Back to the list | Next news |