At the CCGT-225 of Syzran CHPP there was completed overhaul of fuel gas compressor units

13 March 2020

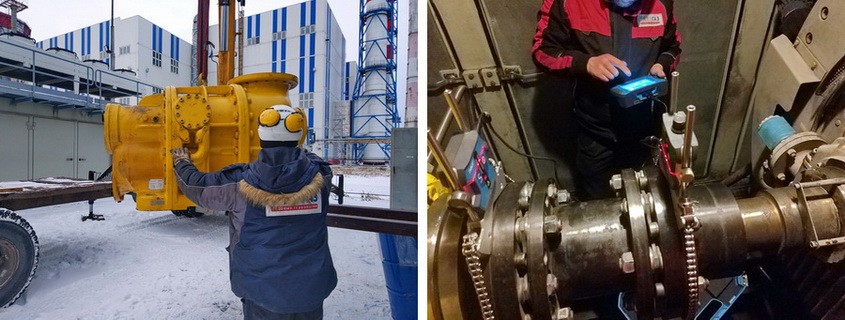

Highly efficient combined-cycle power generating unit CCGT-225 has been operating since October 2012. The designed electric capacity of the CCGT is 225 MW (actual 227.4 MW); the thermal capacity is 110 Gcal / h. The basis of power unit consists of two PG6111FA gas turbine units produced by GE, SST PAC 600 steam-turbine unit of Siemens, and two waste-heat boilers.Fuel feeding to the PG6111FA turbines is carried out by ENERGAS system which comprises gas treatment station and gas booster station consisting of three compressor units (CU). The specialists of the ServicENERGAS Company (part of ENERGAS Group) performed the overhaul of CU-1 and CU-3.

1. Replaced the main elements of the units – screw oil-filled compressors.

2. Local repair and restoration works were carried out.

3. Performed the replacement of consumables including gas filters of 1st and 2nd purification stages and oil filters.

4. The oil was replaced. The CU oil system now uses ester synthetic oil of the new generation ESTSYN CE, which is specially created for units made based on screw compressors.

5. Units were pressure testing – checking all assemblies and connections for tightness.

At the final stage (after start-up and adjustment works and own tests) there was took place integrated testing of equipment under load – in conjunction with gas turbine units. 72-hours testing were conducted stepwise under various turbines capacity modes.

Recall that in January here there was completed inspection type "C" (major overhaul) of gas turbines. The main outcome of the works was to increase the reliability of heat supply for the residents of Syzran.

For the first time during the inspection of generating equipment of Russian power plants, the MAGIC complex was used. For the diagnosis of PG6111FA turbines, the miniature MAGIC Junior robot was used, while the largest element, the rotor, was not removed from the turbo generators. The robot inside the multi-ton units performed a visual, mechanical and electromagnetic assessment of the condition of the equipment, and it produced a detailed map of the state of the nodes. Examination was conducted by GE specialists.

REFERENCE. Syzran CHPP of the Samara branch of T Plus provides electricity and heat supply to industrial consumers and population of Syzran city and Syzran District. The commissioning of new capacities in 2012 made it possible to supply heat to the Central District of Syzran that improved the city's ecology by decommissioning more than 50 small inefficient boiler houses. CCGT-225 is one of the most efficient and technologically advanced facilities of a new generating in the Middle Volga.

PG6111FA turbines at CCGT of the Syzran CHPP are the first General Electric GTU of the 6F series supplied to Russia. In total, more than 20 units of the 6F family operate in our country at power generating units with a total capacity of about 2 GW. Since 2014, the production of GTU of type 6F.03 with a capacity of about 80 MW has been localized at the Russian Gas Turbines LLC plant, a joint venture of GE and Inter RAO PJSC.

Units of 6F series (6F.03, Frame 6FA, PG6111FA) are capable of operating on various types of natural gas, distillate and synthetic fuel. They are also characterized by high effectiveness: these turbines generate up to 87 MW of capacity in a simple cycle and provide efficiency of more than 57% in a combined cycle.

REFERENCE. ENERGAS Group of Companies is recognized leader in gas treatment. Today, 212 booster compressor stations and packaged gas treatment stations of ENERGAS supply 187 power units (with total electrical capacity of 6.49 GW) of leading Russian and foreign manufacturers with fuel.

| Previous news | Back to the list | Next news |