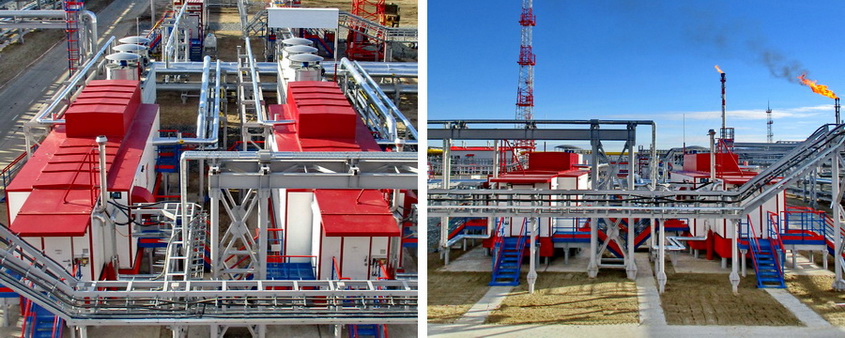

Medium-pressure compressor units at petroleum gas compressor station of Pyakyakha field – 5 years of smooth operation

23 March 2022

These gas-booster units are intended to pumping associated gas of the first separation stage incoming from the oil treatment plant.

Pyakyakha oil and gas condensate field of the LUKOIL-West Siberia LLC is equipped with petroleum gas compressor station (CS) which ensures the gathering of APG from various production facilities of the field and its transportation.

As part of the CS, the four medium-pressure compressor units (CUs) from ENERGAS passed the 5-year period of operation. The units, made based on screw oil-filled compressors, uninterruptedly compress up to 3 MPa associated gas of the first separation stage incoming from the oil treatment plant.

The maximum capacity of each CU is 16,180 m3 / h; gas flow rate is controlled by means of the two-tier regulation system. To measure of compressed APG amount, all the machines are additionally equipped with gas metering assemblies with flow meters.

The additional purification of APG (two-step removal of liquid fraction and solid particles) at the inlet to compressors is carried out by highly efficient coalescing filters-scrubbers integrated in CUs modules and equipped with automatic drainage system.

The delivery lines of units are equipped with a heat exchangers (with a built-in separator and a condensate collector), which cool the compressed associated gas and remove the resulting condensate. As a result, the calculated temperature of the working medium set by the design requirements is provided.

CUs are fully automated. Operation mode as part of the facility of oil-and-gas production complex is uninterrupted with scheduled shutdowns for maintenance.

Block-modular units were designed to meet the extreme operating conditions (minimum air temperature is minus 56°C, average air temperature of the coldest five-day period is minus 46°C), they are equipped with life support systems (heating, ventilation and lighting) and safety systems (fire detection, gas detection, alarm and fire fighting).

Complete with compressor units, ENERGAS has supplied indoor switchgear (with a voltage of 10 kV) and frequency converter of main electric motors (drives). Switchgear provides power supply, and the converter ensures smooth start of machines and step-less regulation of their capacity. Electrical equipment is placed in a separate enclosure and corresponds to the Russian standards on fire resistance, fire and explosion safety, seismic impact, electromagnetic compatibility.

The launch of four medium-pressure CUs is a significant stage of the largest project in the production practice of ENERGAS. During 2017, five more units were put into operation, which were included in the structure of the CS of the Pyakyakha field. This is:

- Booster unit to compress gas from condensate de-ethanization facility;

- Low-pressure CU for compressing APG incoming from the 2nd oil separation stage of OTP;

- Three reciprocating compressor units to transport petroleum gas to the complex gas treatment plant.

REFERENCE:

The Pyakyakha oil and gas condensate field, discovered in 1989, is one of the largest in the Yamal-Nenets Autonomous Area in terms of explored reserves and belongs to the most promising fields of Bolshekhetskaya Depression. Its development became the second project implemented by LUKOIL in the YNAA. The field operator is LUKOIL-West Siberia LLC.

The active phase of development and arrangement of the Pyakyakha OGCF began in 2014, and the field was put into commercial operation on October 25, 2016. A gas turbine power plant with a capacity of 36 MW, an oil treatment plant, a pumping station for a reservoir pressure maintenance system, condensate de-ethanization and condensate stabilization facilities, an acceptance point, a complex gas treatment plant and other production and infrastructure facilities operate here.

| Previous news | Back to the list | Next news |