The gas compressor station at OCTP of the Fedorovskneft OGPD has passed the 10-year milestone of reliable operation

23 December 2021

Since December 23, 2011, this compressor station (CS) has been operating at West-Surgut field - at the site of the Oil Comprehensive Treatment Plant (OCTP) of the Fedorovskneft Oil and Gas Production Department. Operation mode of the CS is nonstop with scheduled shutdowns for maintenance.The CS carries out additional purification and compression of low-pressure associated gas with its subsequent injection at a pressure of 0.6 MPa into the transport gas pipeline. Thus, the maximum possible rational utilization of APG from final separation stage is ensured at the facility.

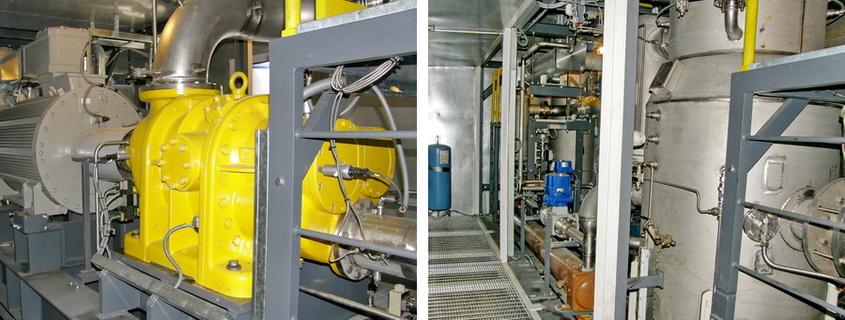

The uninterrupted operation of station is guaranteed primarily by the reliability of main equipment which consists of two compressor units. The CUs, supplied and commissioned by ENERGAS Company, are made based on screw oil-filled compressors. The unit capacity of the packaged units amounts to 2,500 m3 / h; gas flow rate is controlled by a special two-level regulation system.

The additional purification of APG (two-step removal of liquid fraction and solid particles) at the inlet to each compressor is carried out by highly efficient coalescing filters-scrubbers equipped with automatic drainage system.

After purification and compression, the gas is cooled to the calculated values set by the design requirements. It takes place at delivery line of the CU – in shell-and-tube heat exchangers with an integrated separator and a condensate collector. As a result, the dew point temperature of associated gas is decreased and condensation during APG transportation is excluded.

One of the features of the project is the lack of gas pressure at the suction (0 MPa g), which was taken into account at the design and production stages. In particular, the units are equipped with system of quick-acting valves, which allows you to "cut off" intake pipeline from the trunk pipeline and to prevent release of oil from the oil system into inlet filter-scrubber (back draft).

When working "under vacuum", air can enter the gas circuit of CUs. To ensure the safety of the process workflow, the units are equipped with oxygen detection system that determines and controls its content in gas flow.

The problems accompanying compression of high-density APG, which comes from OCTP (Oil Comprehensive Treatment Plant), were solved by increasing the oil and gas operating temperatures in the units, as well as due to using a special lubricant with higher viscosity and high resistance to saturation from the heavy hydrocarbons.

CUs are placed in their own enclosures of arctic type, are fully automated, and equipped with life support systems (heating, ventilation, and lighting) and safety systems (fire detection and fire extinguishing, gas detection, alarm).

The CS at OCTP of the Fedorovskneft OGPD is one of the "small" compressor stations of the Intra-field Petroleum Gas Gathering and Using Division (UVSING) of Surgutneftegas PJSC. Its launch was part of the company's special program of activities.

Most of these "small" CS are used for offtake of associated gas from the end stages of oil separation, that allows reach the maximum level of the useful use of APG. For this important benchmark, Surgutneftegas has been deservedly leading among Russia's largest extraction companies for a number of years.

REFERENCE:

The West-Surgut oil field is located in the Surgut region of the Khanty-Mansi Autonomous Area, near the city of Surgut. Opened in 1963, put into operation in 1965.

| Previous news | Back to the list | Next news |