Power supply complex for the Kharasavey field in Yamal is being equipped with ENERGAS fuel gas treatment facility

15 May 2020

As part of the project to equip the Kharasavey field of PJSC Gazprom, a power supply complex is being created here to supply electricity to construction sites. The operating company and the owner of the power supply complex is Allocation Hub LLC.As the primary source of power supply, six gas-reciprocating power plants (GRPP) MWM 2020 V20 type with a capacity of 2 MW each and two GRPPs MWM 2020 V12 type with a capacity of 1.2 MW each are used. The main consumer of electricity will be a rotational camp for 5,000 people.

The generating facility will also include four mobile automated gas-turbine power plants PAES-2500 with a rated capacity of 2.5 MW each. PAESs are designed to supply electricity to hydraulic flushing units.

The fuel for power supply complex is natural gas produced at the field. Its design parameters on purity, temperature, pressure and flow will be provided by the ENERGAS fuel gas treatment facility (FGTF). The maximum capacity of the facility is 8,000 m3 / h, including: gas consumption for gas reciprocating units – 5,000 m3 / h, for PAES turbines – 3,000 m3 / h.

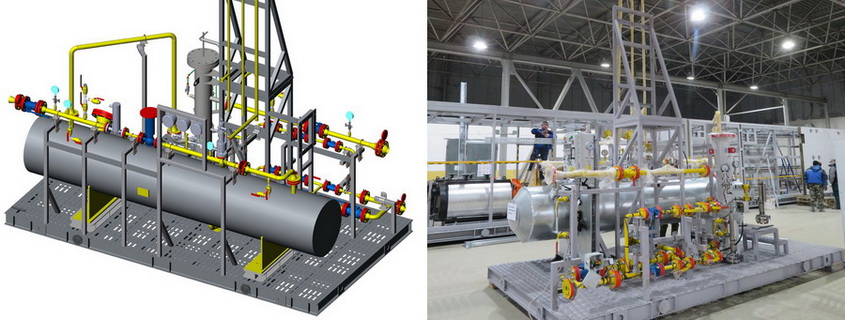

FGTF is a multifunctional complex of two modules operating in cascade scheme. Fuel gas treatment module (FGTM) No. 1 is made on an open frame and is intended for preliminary separation, filtration and pressure reduction of the incoming gas. FGTM-1 comprises the following process equipment:

- Separator-slugcatcher with a volume of 1 m3;

- Two-stage filter coalescer, purification rate is 99,9% for the particles larger than 5 microns;

- Gas condensate gathering and storage unit with 10 m3 underground tank;

- Reduction system (gas pressure at the inlet is 12.7 MPa, at the outlet is 5.45 MPa).

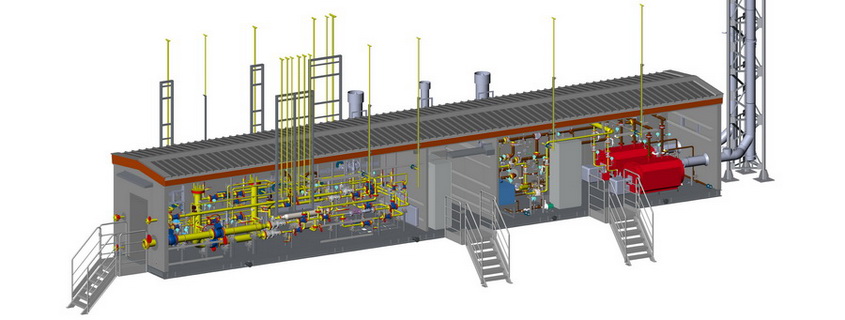

After the first stage of treatment, the fuel gas enters to module No. 2, where the its final purification, flow measurement, heating and additional pressure reduction are happening. FGTM-2 is a block-box, divided into several compartments, which accommodate equipment for various purposes:

- Filtration system with coalescing elements, purification degree is 100% for the liquid fraction and 99.9% for solid particles larger than 3 microns;

- Condensate drainage module with 5 m3 tank;

- Gas commercial metering subassembly, consisting of measuring and control lines with ultrasonic flow meters;

- Gas heating unit with a capacity of 500 kW based on a shell-and-tube heat exchanger;

- Four-line reduction system (gas pressure at the inlet is 5.45 MPa, at the outlet – 0.45 MPa for GRPP and 1.25 MPa for PAES);

- Output unit of monitoring with manometer and thermometer, pressure and temperature sensors;

- Packaged boiler room for the preparation of the heat carrier, including two boilers with a total thermal capacity of 0.6 MW.

FGTM-2 is equipped with necessary engineering systems, including life support systems (heating, ventilation and lighting) and safety (fire detection, gas detection, alarm and fire fighting).

Fuel gas treatment facility is fully automated. Automated control system performs launch (and preparing for start), shutdown, and maintaining the optimal operation mode; controls the process parameters; provides automatic protection and alarm; handles the parameters of the workflow and emergency events with the issuance of information via a standard exchange protocol.

The local ACS is made on the basis of modern microprocessor technology using software and cross-connect equipment of the latest generation; it is housed in a special compartment of the module No. 2, separated from the process part with a gas-tight fire-resistant partition.

The control system will be integrated with the upper level of the APCS of the power supply complex; it will provide remote control of the FGTF, indoors gas hazard monitoring, output of information on the status of all elements to the operator panel.

FGTF is supplied with a high degree of prefabrication (availability factor of 0.98+), what significantly reduces the duration of the construction and mounting works as well as adjustment activities. The coefficient of technical use is 0.92+; coefficient of reliability of starts is 0.95+. Assigned resource (operating life) – 20 years.

After the successful completion of preliminary workshop testing, the equipment has been delivered to the operation site. The entire range of pre-launching activities (erection supervision, adjusting, own and integrated tests, staff training) will be performed by the specialists of ServicENERGAS, a member of the ENERGAS Group.

REFERENCE. The Kharasavey gas condensate field is located in the Yamal-Nenets Autonomous Area, mainly on the land of the Yamal Peninsula and partially in the Kara Sea. By the size of gas reserves (2 trillion cubic meters), it belongs to the unique category.

In March 2019, Gazprom began full-scale development of the Cenomanian-Aptian deposits here. The start of production is scheduled for 2023. In the future, it is planned to develop deeper Neocom-Jurassic deposits. The field is being equipped by AO Gazstroyprom, the sole contractor of Gazprom Group enterprises.

| Previous news | Back to the list | Next news |