ENERGAS has supplied process equipment for the natural gas liquefaction plant in Tyumen Region

9 June 2021

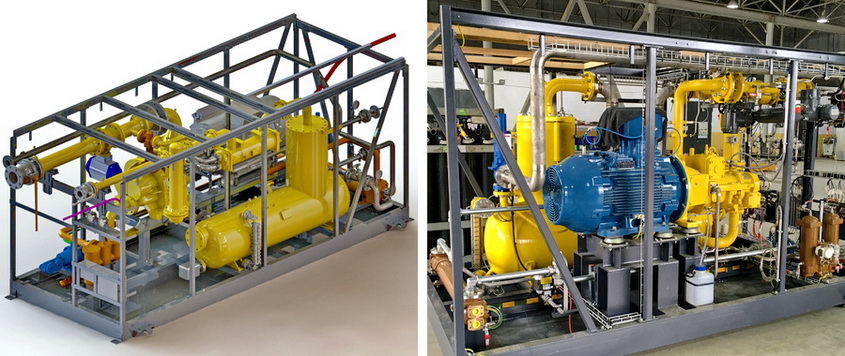

In the Tyumen Region, at the site of the Tobolskaya gas distribution station, a plant for the production, storage and shipment of liquefied natural gas, the LNGP Tobolsk, is being built. Two ENERGAS boil-off gas recovery units will be integrated into the structure of the LNGP. They are designed to return methane vapor generated during storage to the production cycle of gas liquefaction.After successful completion of factory tests, this equipment has been delivered to the customer. Phased commissioning of the units will be implemented by the ServicENERGAS Company (part of ENERGAS Group). Technicians will perform erection supervision, start-up and adjustment works, own testing, comprehensive check of units as part of facility, as well as training of operating staff.

The units are made on the basis of modern compressor technologies, screw oil-filled compressors were applied as their main element. The pressure of the boil-off gas is boosted from 0.27 to 1.28 MPa. The maximum volume capacity of each unit is 889 Nm3 / h (650 kg / h), gas flow rate is controlled in the range from 0 to 100% of nominal using a special two-circuit regulation system.

Compressor units are fully automated and will operate in alternating mode (1 in work, 1 in hot-standby). Operating unit gives the required gas flow rate, while the second compressor is ready to be switched on by ATS (automatic transfer switch). If it is necessary to operate both units in parallel for a common gas manifold, the control system implements a group regulation mode, evenly distributing the operational load between simultaneously operating units.

The process flow scheme of the equipment provides for stable maintenance of the designed temperature of compressed boil-off gas (+40°C) necessary for its recovery.

The project requirements for gas purity are guaranteed by the multistage filtration system – each unit is equipped with an inlet protective strainer, a gas-oil separator of the 1st stage of purification and a coalescing (safety) filter of the 2nd stage. As a result, the content of impurities at the outlet does not exceed 1 ppmw (mg / kg).

The oil system uses an ester synthetic oil of the new generation, which is specially designed for units with screw compressors. ESTSYN oil ensures efficient operation, increases reliability and service life of the equipment.

| Previous news | Back to the list | Next news |