Booster compressor station of fuel gas for CCGT unit of Mogilev CHPP-3: three years of uninterrupted operation

12 April 2017

Mogilev CHPP-3 will provide electricity for houses, industrial enterprises, administrative and domestic buildings at the north part of the city. Since 2014 as a part of the power plant there is combined cycle gas turbine unit (CCGT unit).Power generating unit consists of two gas turbine units Siemens SGT-300 with installed capacity of 7.5 MW of each, steam turbine with capacity of 3.5 MW and two waste-heat boilers with steam capacity of 17.5 ton / h. Overall efficiency of combined cycle gas turbine unit is 88%.

The high-performance CCGT unit operates in cogeneration mode and integrated into an existing process flow diagram. Electric capacity is 18.5 MW, thermal – 23.2 MW. The fuel for CCGT unit is natural gas.

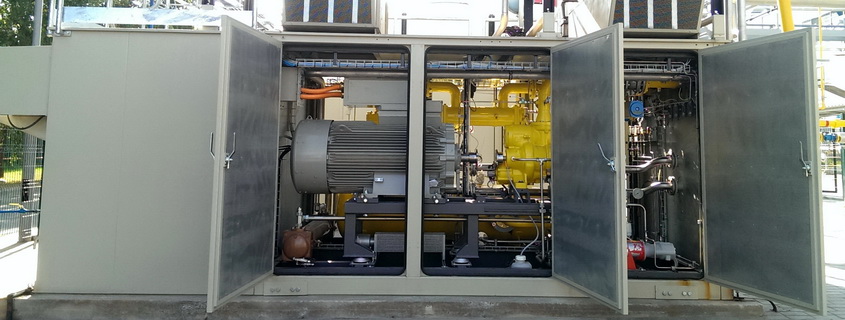

The compression of the fuel gas and its feeding to the turbines under required operating pressure of 1.9…2.6 MPa are implemented by the booster compressor station (BCS), supplied by the company ENERGAS. BCS is composed of two compressor units (CU) of screw type; capacity of each is 3,000 m3 / h.

CU are placed in separate weatherproof shelters; they are equipped with individual ACS and group system of automated control with the function of transmitting data to APCS of upper level, as well as with two-level systems of capacity control.

Since BCS commissioning, the operating time of units was counted more than 20 000 hours. Currently there is completed comprehensive maintenance of the equipment. Scheduled tasks were carried out by specialists of the LLC ServicENERGAS (companies group ENERGAS).

In the course of maintenance the following works there were performed:

- replacement of consumables (gas and oil filters, oil in the bearings of the motors);

- check the alignment of rotating units (compressors and motors);

- gaps measure and checking the status of the internal components of the compressors;

- adjustment and calibration of position sensors and positioning of valves and hydraulic controllers;

- functional tests of the oil system and cooling system of the compressor units;

- verification of operational parameters of the BCS and their adjustment;

- troubleshooting; issuing recommendations on components replacement.

REFERENCE. The upgrade project of Mogilev CHPP-3 by the construction of the CCGT unit was implemented by company Technoserv – the largest system integrator operating in Russia, CIS and Europe. Construction customer is RUE Mogilevenergo.

Earlier capacity of the facility was 210 Gcal / h without generating electricity. Currently CHPP able to produce 10% more heat and generate electric power in volume of 18.5 MW.

| Previous news | Back to the list | Next news |