At the gas turbines test bench of Proton-PM there has been completed overhaul of fuel gas compressor station

1 December 2020

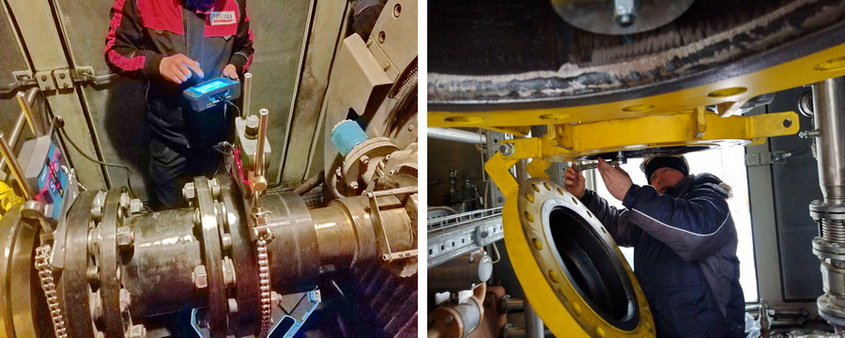

The experts of the ServicENERGAS (part of ENERGAS Group) performed the overhaul of the booster compressor station operating as part of the complex for testing gas turbine units (GTU) of Proton-Perm Motors PJSC. This BCS feeds the testable turbines with gas that meets the specified parameters in terms of purity, temperature, pressure and flow rate.

1. Replaced the main element of the station – screw oil-filled compressor.

2. Local repair and restoration works were carried out.

3. Performed the replacement of consumables including gas filters of 1st and 2nd purification stages and oil filters.

4. The oil was replaced. The BCS oil system now uses ester synthetic oil of the new generation ESTSYN CE, which is specially created for units made based on screw compressors.

5. Station was pressure testing – checking all assemblies and connections for tightness.

6. Comprehensive maintenance of equipment according to Regulations-8000 was carried out.

7. Performed the start-up and adjustment works and own tests of BCS.

At the final stage there was took place comprehensive testing of compressor station under load – in conjunction with gas turbine unit. 72-hours testing were conducted stepwise under various turbine capacity modes.

BCS for fuel gas was installed here by ENERGAS in December 2011. Equipment was specially devised to operate in conditions of various tests duration and high intensity of starts.

The project requirements for the gas purity are ensured by the multistage filtration system of BCS: inlet protective strainer, gas-oil separator of the 1st stage of purification and coalescing (safety) filter of the 2nd stage. Thus, compliance of the fuel with the set norms is guaranteed: the content of mechanical impurities in gas at the outlet is no more than 2 ppmw (mg / kg), the degree of purification from solid particles larger than 10 microns and liquid fraction is 100%.

Highly efficient compressor module gives a high gas compression ratio: the pressure at the suction is 0.5 MPa, the pressure at the delivery line can be provided in the range of 1.6 ... 4.5 MPa – depending on the type and settings of conjugated GTU and the testing algorithm.

The process flow scheme provides for the stable maintenance of the calculated fuel temperature. The delivery line of the BCS is equipped with a shell-and-tube heat exchanger that cools the working medium and guarantees the optimum gas supply temperature set by the turbo unit manufacturer.

The volume productivity of compressor station varies from 2,500 to 11,000 m3 per hour. The actual gas flow rate depends on the capacity and dynamics of the load of associated turbine, and is controlled in the range from 0 to 100% of nominal. For this purpose, a special two-tier productivity regulation system is used, which allows the BCS to respond as quickly and correctly as possible to changes in the operating mode of the testable GTU and fluctuations in the parameters of the inlet pipeline, as well as, if necessary, to operate the station in the gas recirculation mode.

Packaged BCS is fully automated and is housed in its own all-weather shelter, equipped with life support systems (heating, ventilation, and lighting). According to safety requirements, process unit is equipped with fire detection, gas detection, alarm and fire fighting systems.

REFERENCE:

Among the priorities of the ENERGAS Group are production, comprehensive commissioning and maintenance of gas treatment and compression units for generating facilities in the electric power industry, oil and gas complex and industrial enterprises. Today, the ENERGAS process equipment provides high-quality fuel for 200 gas turbines and gas-reciprocating units with a total capacity of over 6.5 GW.

| Previous news | Back to the list | Next news |