The associated gas compressor station has been reliably operating at South-Nyurymskaya GTPP for 5 years

30 August 2022

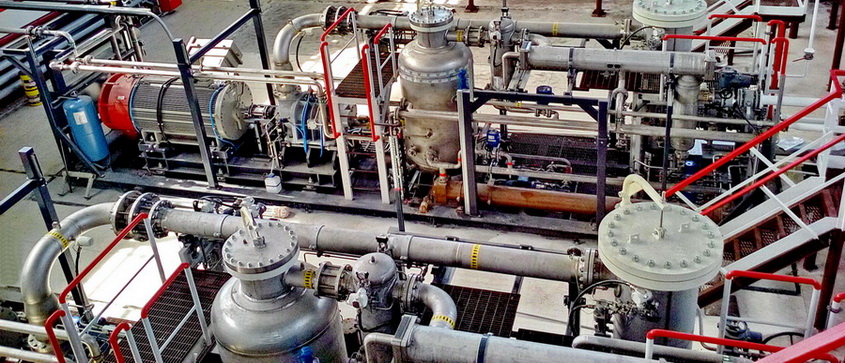

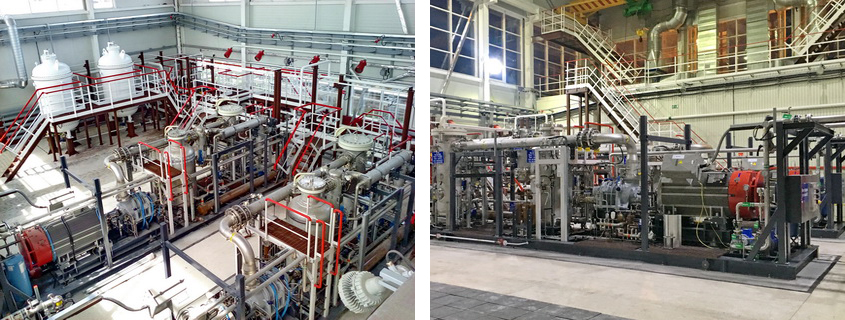

The compressor station of the hangar type supplies turbines with fuel with the required parameters for purity, temperature, pressure and flow rate.

The gas turbine power plant of the South-Nyurymskoye field of PJSC Surgutneftegas was put into operation in August 2017. The installed electric capacity of the GTPP is 8 MW.

GTPP operates in the cogeneration cycle. Electric power generation is provided here by two Ural-4000 gas-turbine power units. For generation of the heat there are installed UT-55-10 waste heat exchangers with total thermal capacity of 8 MW.

Ural-4000 power unit was devised and is mass-produced by the Perm engine-builders, the companies UEC-Aviadvigatel and UEC-Perm Motors. The design is based on the GTU-4P gas turbine unit, created on the basis of the D-30 aircraft engine, one of the most reliable in the history of the Russian aviation industry. The rated electric capacity of the power unit is 4 MW.

GTPP uses associated petroleum gas as a fuel. Thus, the supply of production and infrastructure facilities with their own energy resources is combined with the rational utilization of APG and improvement of ecological situation at the field.

The operating mode of the gas turbine power plant is round-the-clock, year-round. The GTPP equipment has full redundancy, that excludes its full shutdown when conducting preventive and repair works.

A significant contribution to the reliability and efficiency of GTPP-8 operation is made by the booster compressor station for associated gas. For 5 years, this BCS has been supplying turbines with fuel with specified parameters in terms of purity, temperature, pressure and flow rate.

BCS of the hangar type consists of two compressor units (CUs) which housed in separate building. The units, supplied and commissioned by ENERGAS Company, are made based on screw oil-filled compressors. The maximum volume capacity of each CU amounts to 6,000 m3 / h; gas flow rate is controlled by a special two-level regulation system.

Process equipment provides a high compression ratio: the minimum APG inlet pressure is 0.2 MPa, the specified outlet pressure is 2 MPa. The purification of gas entering the compressors (two-step removal of liquid fractions and solid particles) is carried out by highly efficient coalescing filters-scrubbers with automatic drainage system.

The delivery line of each CU is equipped with a heat exchanger (with a built-in separator and a condensate collector), which cools the compressed APG, removes the resulting condensate and maintains the calculated temperature of the gas fuel set by the turbines manufacturer and design requirements.

BCS is fully automated. Local control systems of compressor units are tied by a group regulation algorithm and integrated with the upper level of the facility's APCS. The joint ACS provides remote control of equipment, automatic protections and alarm; monitors the process parameters and gas pollution in the machine room of the BCS; handles the parameters of the workflows and emergency events; issues information to the operator panel.

Operation mode of gas booster units as part of the power plant is continuous, with scheduled shutdowns for maintenance.

REFERENCE:

The South-Nyurymskoye oil field is located in the north of the Tyumen Region, in the Uvat area and adjacent areas of the Khanty-Mansi Autonomous Area. Discovered in 2010, put into operation in 2016. Geological reserves of industrial categories are estimated at about 20 million tons of oil.

The field is being developed by Surgutneft OGPD, the oldest Oil and Gas Production Departments of PJSC Surgutneftegas. The construction of GTPP-8 was carried out here as part of the energy project of company to create its own generating capacities.

| Previous news | Back to the list | Next news |