Comprehensive treatment of fuel gas is one of the main factors in the efficiency of autonomous power supply complexes of enterprises

ENERGAS Group has completed another project in the field of gas treatment and fuel supply for decentralized power supply complexes of industrial enterprises. The cogeneration power plant and boiler house of the new HAYAT Plant in Kaluga Region have been equipped with the ENERGAS fuel gas treatment system consisting of a block-type gas treatment station and a booster compressor station.

The implementation of such projects is always among the priorities of the Group. This work includes the following main stages: detailed designing, production, comprehensive commissioning (erection supervision, starting-up and adjustment, testing) and maintenance of gas treatment and compression units.

Units are devised and manufactured considering the operating conditions, composition, quality and characteristics of the source gas, type and capacity of conjugated gas-consuming gensets, general projected tasks and special customer requirements.

It should be noted that modern technologies for the treatment of gas fuel for generating facilities of various sizes are successfully used by ENERGAS specialists based on the unique engineering and organizational experience accumulated over 15 years.

HAYAT Russia (subdivision of Hayat Kimya Group) has increased its production capacities – a large plant for the production of sanitary and hygienic paper products was built at the Borovsk site of the Kaluga special economic zone. The owner of enterprise is Hayat Consumer Goods LLC.

The new plant in the Kaluga Region is an innovative space, created on the basis of fully automated and resource-saving systems. This high-tech project has strengthened the position of HAYAT Russia as the country's largest manufacturer of toilet paper, paper towels and napkins, with a total volume of 280 thousand tons of products per year.

At the site of enterprise, an autonomous (decentralized) power supply complex has been built to supply production with its own energy resources. Electricity is generated by the two SOLAR Mars 100 gas turbine units (GTU) with an installed capacity of 10 MW each.

The production of high-potential process steam is provided by the two waste heat boilers with a productivity of 15 t / h each, which use the heat from exhausted hot gases (products of fuel combustion in the turbines). Therefore, the cogeneration cycle significantly improves the overall fuel effectiveness.

In addition to the cogeneration power unit, the structure of the power supply complex includes an auxiliary gas boiler house. The system of conversion of gas into electricity and heat resources required to produce paper products, introduced at the new HAYAT plant, provides for achieving an efficiency of 80%.

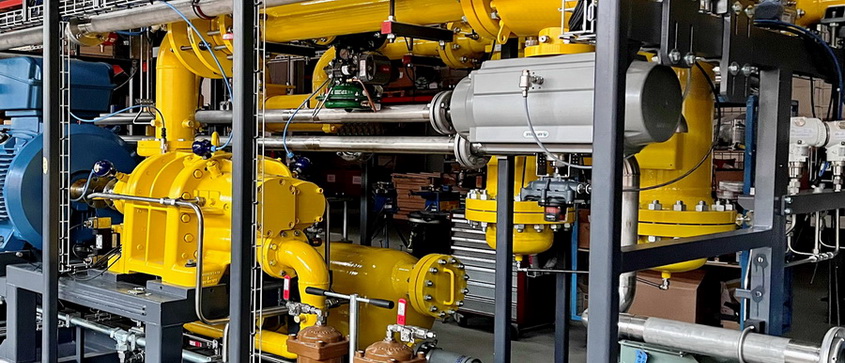

One of the main factors of the reliable and efficient operation of generating equipment is the quality of fuel gas. The supply of the GTU turbines and boiler house with fuel with the specified design parameters in terms of purity, temperature, pressure and flow rate is carried out by the ENERGAS multifunctional system – a block-type gas treatment station (BGTS) and a booster compressor station (BCS).

BGTS and BCS were commissioned in advance by the specialists of ServicENERGAS (ENERGAS Group), what allowed the factory power engineers to carry out a full range of tests of the power unit and put it into operation on schedule.

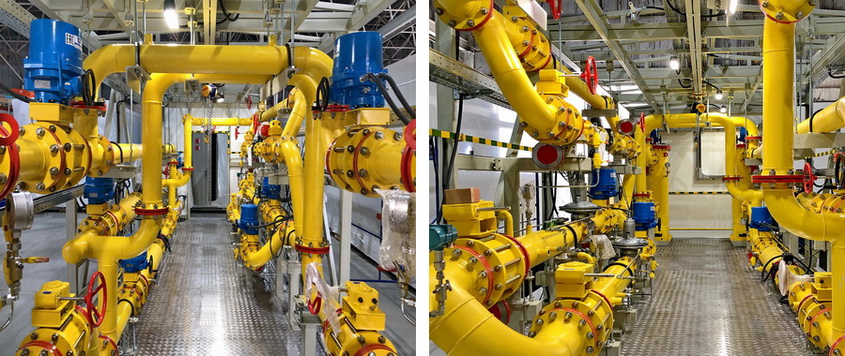

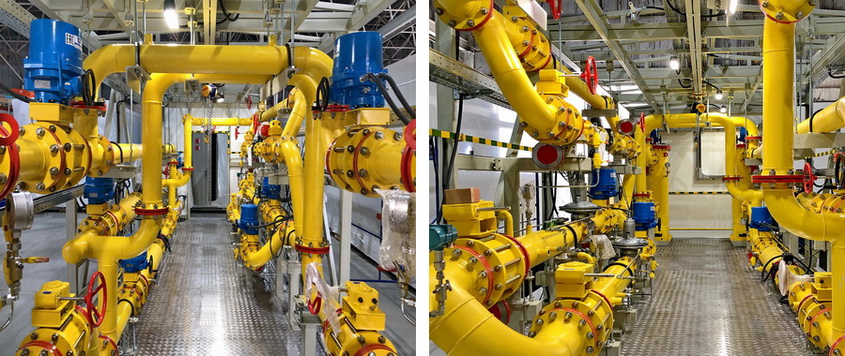

The block-type gas treatment station, manufactured under a special project, is used for metering, filtration, pressure reduction and quality control of gas. The throughput of the BGTS is 9,317 m3 / h – similar to the total fuel consumption of GTU and boiler house.

Station is equipped with separation system with coalescing filters, the purification efficiency is 99.9% for solid particles larger than 3 microns and 100% for droplet moisture. Filters are equipped with pressure differential sensors which signal the contamination of replaceable elements.

The purified gas is divided into two flows. The first one is directly headed to the BCS and then to the GTU turbines, the second one passes through a reduction module, which reduces the gas pressure and stabilizes it at the level required for feeding to the boilers (0.3 MPa).

At BGTS there is measured total volume of gas supplied to the power supply complex (commercial metering) and separately measured volume of fuel for the boiler house (process metering). Data are transmitted via communication channels to the upper level of the APCS. Metering units with a relative error of no more than 1.5% made based on flow meters of ultrasonic type.

Both gas delivery lines (outlet pipelines) of the BGTS are equipped with fuel quality control assemblies with various measuring and analytical equipment.

The gas treatment station is housed in a separate all-weather block-box with the integration of elements on a single frame, equipped with systems of working and emergency lighting, premise heating and ventilation, safety systems.

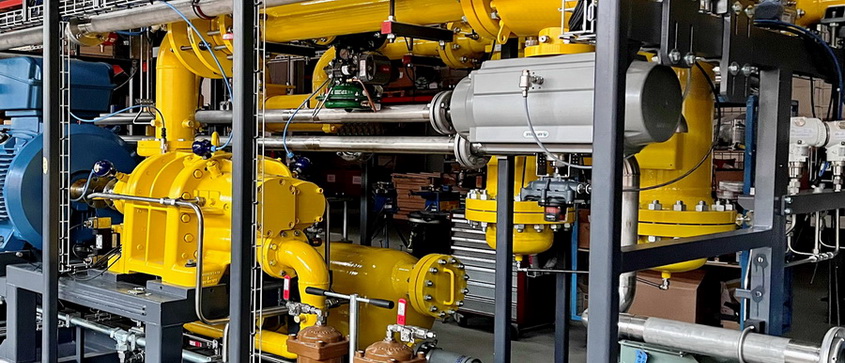

The booster compressor station, which is part of the ENERGAS multifunctional system, is intended to compress the fuel treated in the BGTS and feed it to the Mars 100 turbines at a pressure of 2.6 MPa.

BCS operates without a backup, fully providing the fuel consumption of the generating facility. At the same time, the operation mode of the booster machine as part of the power unit is continuous with scheduled shutdowns for maintenance.

The gas compressor unit made based on screw oil-filled compressor with a volume capacity of 6,336 Nm3 / h. The actual gas flow rate depends on the GTU load and is controlled in the range from 0 to 100% of nominal. For control, a special two-circuit regulation system is applied.

Taking into account the stringent requirements for the purity of fuel gas, the basic filtration system of the BCS, consisting of an oil-gas separator of the 1st stage of purification and a coalescing filter of the 2nd stage, is enhanced due additional elements: 1) a protective strainer is installed on the suction line of the compressor station; 2) a safety filter for fine purification of gas is built into BCS module. Eventually, the content of impurities in the fuel at the inlet to the GTU shut-off valve block does not exceed 0.1 ppmw (mg / kg).

The process flow scheme of the BCS provides for stable maintenance of the design fuel temperature necessary for the normal operation of turbines. The delivery line of the station is equipped with a heat exchanger which cools the working medium to the level of the optimum gas supply temperature (+70°C) set by the GTU manufacturer (Solar Turbines) and terms of the project.

Gas booster unit is placed in its individual compact enclosure of container type equipped with life support systems. According to safety requirements, BCS is equipped with fire detection, gas detection, alarm and fire extinguishing autonomous systems.

Gas treatment station and compressor station are fully automated. Their control systems are made based on microprocessor technology, using modern software, switching equipment, channels and protocols of communication. The local ACSs have been integrated into facility's APCS. They provide remote control of units, and automatic protections and alarm; they monitor the process parameters and indoor gas hazard, handle the parameters of the workflows and emergency events, issue information to the operator panel.

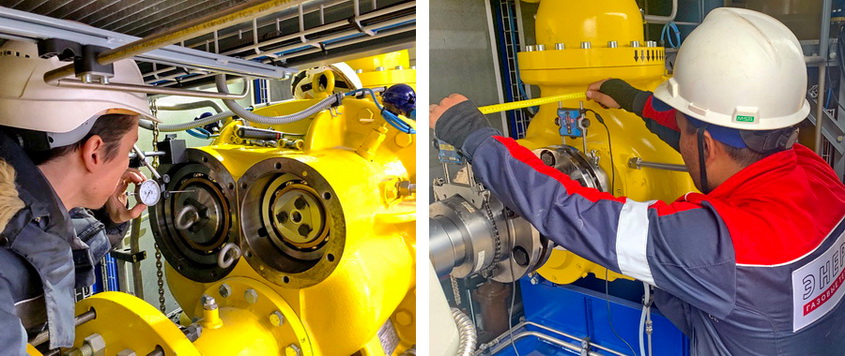

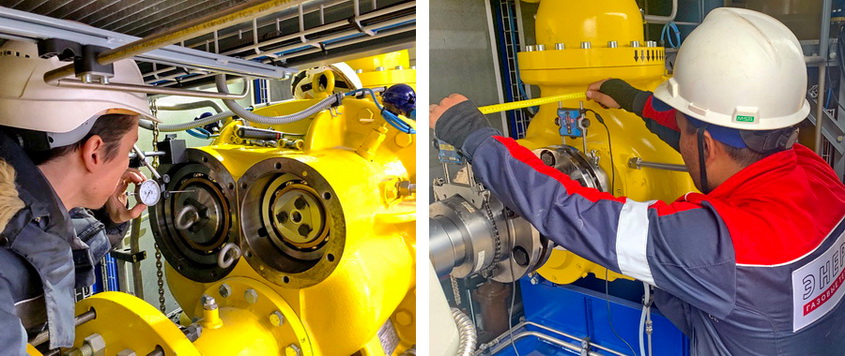

In the course of commissioning of the entire fuel gas treatment system (BGTS and BCS) for the factory power supply complex, ENERGAS service engineers performed erection supervision, starting-up and adjustment, its own and comprehensive tests of equipment, as well as conducted training of operational personnel.

REFERENCE:

Hayat Kimya Group of Companies (part of the Turkish holding HAYAT) has been working in the FMCG segment since 1987. It specializes in the production of cleaning products and detergents, sanitary and hygienic paper products and hygiene products. It is ranked 41st among the largest exporters in Turkey and 47th in the top 500 of the Istanbul Chamber of Commerce.

REFERENCE:

The Kaluga special economic zone includes the Lyudinovo and Borovsk sites, located in the south and north of the Kaluga Region, respectively. On the territory of the SEZ, regional advantages regarding access to engineering, transport and business infrastructure, federal tax incentives and customs preferences are all available.

The implementation of such projects is always among the priorities of the Group. This work includes the following main stages: detailed designing, production, comprehensive commissioning (erection supervision, starting-up and adjustment, testing) and maintenance of gas treatment and compression units.

Units are devised and manufactured considering the operating conditions, composition, quality and characteristics of the source gas, type and capacity of conjugated gas-consuming gensets, general projected tasks and special customer requirements.

It should be noted that modern technologies for the treatment of gas fuel for generating facilities of various sizes are successfully used by ENERGAS specialists based on the unique engineering and organizational experience accumulated over 15 years.

In total, the ENERGAS process equipment today provides high-quality fuel for 230 gas-turbine and gas-reciprocating units with a total capacity of over 6.7 GW.

HAYAT Russia (subdivision of Hayat Kimya Group) has increased its production capacities – a large plant for the production of sanitary and hygienic paper products was built at the Borovsk site of the Kaluga special economic zone. The owner of enterprise is Hayat Consumer Goods LLC.

The new plant in the Kaluga Region is an innovative space, created on the basis of fully automated and resource-saving systems. This high-tech project has strengthened the position of HAYAT Russia as the country's largest manufacturer of toilet paper, paper towels and napkins, with a total volume of 280 thousand tons of products per year.

At the site of enterprise, an autonomous (decentralized) power supply complex has been built to supply production with its own energy resources. Electricity is generated by the two SOLAR Mars 100 gas turbine units (GTU) with an installed capacity of 10 MW each.

SOLAR Mars 100 is a high efficiency gas turbine unit designed primarily for long-term operation in industrial systems. Mars 100 turbines are characterized by high reliability, durability, ease of maintenance, as well as low emissions due to the low-emission SoLoNOx combustion chamber.

The production of high-potential process steam is provided by the two waste heat boilers with a productivity of 15 t / h each, which use the heat from exhausted hot gases (products of fuel combustion in the turbines). Therefore, the cogeneration cycle significantly improves the overall fuel effectiveness.

In addition to the cogeneration power unit, the structure of the power supply complex includes an auxiliary gas boiler house. The system of conversion of gas into electricity and heat resources required to produce paper products, introduced at the new HAYAT plant, provides for achieving an efficiency of 80%.

One of the main factors of the reliable and efficient operation of generating equipment is the quality of fuel gas. The supply of the GTU turbines and boiler house with fuel with the specified design parameters in terms of purity, temperature, pressure and flow rate is carried out by the ENERGAS multifunctional system – a block-type gas treatment station (BGTS) and a booster compressor station (BCS).

BGTS and BCS were commissioned in advance by the specialists of ServicENERGAS (ENERGAS Group), what allowed the factory power engineers to carry out a full range of tests of the power unit and put it into operation on schedule.

The block-type gas treatment station, manufactured under a special project, is used for metering, filtration, pressure reduction and quality control of gas. The throughput of the BGTS is 9,317 m3 / h – similar to the total fuel consumption of GTU and boiler house.

Station is equipped with separation system with coalescing filters, the purification efficiency is 99.9% for solid particles larger than 3 microns and 100% for droplet moisture. Filters are equipped with pressure differential sensors which signal the contamination of replaceable elements.

The purified gas is divided into two flows. The first one is directly headed to the BCS and then to the GTU turbines, the second one passes through a reduction module, which reduces the gas pressure and stabilizes it at the level required for feeding to the boilers (0.3 MPa).

At BGTS there is measured total volume of gas supplied to the power supply complex (commercial metering) and separately measured volume of fuel for the boiler house (process metering). Data are transmitted via communication channels to the upper level of the APCS. Metering units with a relative error of no more than 1.5% made based on flow meters of ultrasonic type.

Both gas delivery lines (outlet pipelines) of the BGTS are equipped with fuel quality control assemblies with various measuring and analytical equipment.

The gas treatment station is housed in a separate all-weather block-box with the integration of elements on a single frame, equipped with systems of working and emergency lighting, premise heating and ventilation, safety systems.

The booster compressor station, which is part of the ENERGAS multifunctional system, is intended to compress the fuel treated in the BGTS and feed it to the Mars 100 turbines at a pressure of 2.6 MPa.

BCS operates without a backup, fully providing the fuel consumption of the generating facility. At the same time, the operation mode of the booster machine as part of the power unit is continuous with scheduled shutdowns for maintenance.

The gas compressor unit made based on screw oil-filled compressor with a volume capacity of 6,336 Nm3 / h. The actual gas flow rate depends on the GTU load and is controlled in the range from 0 to 100% of nominal. For control, a special two-circuit regulation system is applied.

Taking into account the stringent requirements for the purity of fuel gas, the basic filtration system of the BCS, consisting of an oil-gas separator of the 1st stage of purification and a coalescing filter of the 2nd stage, is enhanced due additional elements: 1) a protective strainer is installed on the suction line of the compressor station; 2) a safety filter for fine purification of gas is built into BCS module. Eventually, the content of impurities in the fuel at the inlet to the GTU shut-off valve block does not exceed 0.1 ppmw (mg / kg).

The process flow scheme of the BCS provides for stable maintenance of the design fuel temperature necessary for the normal operation of turbines. The delivery line of the station is equipped with a heat exchanger which cools the working medium to the level of the optimum gas supply temperature (+70°C) set by the GTU manufacturer (Solar Turbines) and terms of the project.

Gas booster unit is placed in its individual compact enclosure of container type equipped with life support systems. According to safety requirements, BCS is equipped with fire detection, gas detection, alarm and fire extinguishing autonomous systems.

Gas treatment station and compressor station are fully automated. Their control systems are made based on microprocessor technology, using modern software, switching equipment, channels and protocols of communication. The local ACSs have been integrated into facility's APCS. They provide remote control of units, and automatic protections and alarm; they monitor the process parameters and indoor gas hazard, handle the parameters of the workflows and emergency events, issue information to the operator panel.

In the course of commissioning of the entire fuel gas treatment system (BGTS and BCS) for the factory power supply complex, ENERGAS service engineers performed erection supervision, starting-up and adjustment, its own and comprehensive tests of equipment, as well as conducted training of operational personnel.

REFERENCE:

Hayat Kimya Group of Companies (part of the Turkish holding HAYAT) has been working in the FMCG segment since 1987. It specializes in the production of cleaning products and detergents, sanitary and hygienic paper products and hygiene products. It is ranked 41st among the largest exporters in Turkey and 47th in the top 500 of the Istanbul Chamber of Commerce.

REFERENCE:

The Kaluga special economic zone includes the Lyudinovo and Borovsk sites, located in the south and north of the Kaluga Region, respectively. On the territory of the SEZ, regional advantages regarding access to engineering, transport and business infrastructure, federal tax incentives and customs preferences are all available.