Gas gathering and transportation facilities

Gas gathering and transportation is one of the priority activities of the company ENERGAS. To date, we have implemented more than 40 such projects in 26 fields.

The equipment of ENERGAS constitutes the basis of compressor stations of petroleum gas, compressor stations of low separation stages, vacuum compressor stations, where additional treatment, compression and injection of gas into the transport pipeline are carried out.

A considerable experience has been accumulated that has no analogues in Russia, when working with low-pressure associated petroleum gas (from -0.05 MPa g). More than 70 of our units perform gathering and pumping of low-pressure APG at the following facilities of the oil and gas production complex:

- oil processing and pumping shops;

- oil verification departments;

- booster pumping stations;

- oil treatment units;

- central production facilities;

- terminal separation units;

- main transfer pumping stations;

- preliminary water removal units;

- complex gas treatment plants.

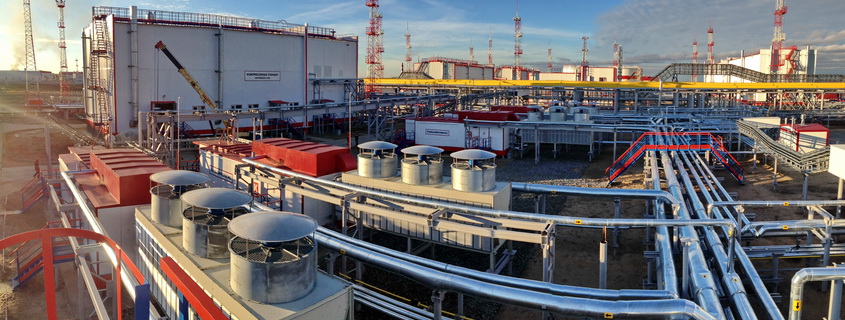

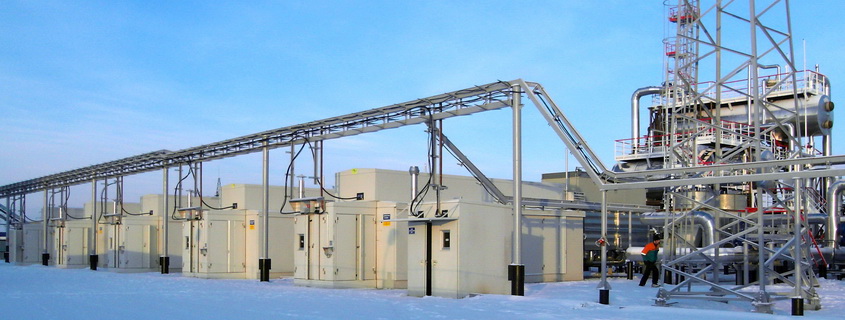

EXAMPLE OF PROJECT IMPLEMENTATION

Pyakyakhinskoye oil and gas condensate field of LLC LUKOIL-Western Siberia is equipped with a petroleum gas compressor station for APG gathering and transportation. There are 9 compressor units (CU) of various types and purposes that are supplied by the company ENERGAS:

- low pressure compressor unit. CU with capacity of 101 ... 2 160 m3 / h is pumping APG from the second stage of oil separation of OTU and gas from terminal separation unit;

- 4 block-modular compressor units for compression of associated gas coming from the first stage of oil separation. Capacity of each CU is 16 180 m3 / h;

- booster compressor unit of screw type. Gas flow rate is 4,660 ... 18,025 m3 / h. The functional of this CU is compression of gas from the condensate deethanization unit;

- 3 reciprocating compressor units with a capacity of 34 240 m3 / h. CU on the basis of reciprocating four-row single-stage compressors compress petroleum gas from facilities of the field up to 11 MPa for subsequent transportation to GPF.

The equipment is designed taking into account extreme operating conditions (minimum air temperature - minus 56 ° С, temperature of the coldest five-day period - minus 46 ° С). Operating mode is automatic, continuous. To measure APG flow rate, each CU is additionally equipped with a gas metering unit.

All units, except reciprocating, are placed in separate block-boxes, equipped with life support systems (heating, ventilation, lighting) and security (fire detection, fire-fighting, gas detection). In accordance with the design, the reciprocating CUs are located in a separate fundamental structure.

The whole cycle of prelaunch works, including supervision, adjustment, individual testing and integrated testing in the structure of the petroleum gas compressor station, was carried out by specialists of LLC ServicENERGAS (group of companies ENERGAS).

The equipment of ENERGAS constitutes the basis of compressor stations of petroleum gas, compressor stations of low separation stages, vacuum compressor stations, where additional treatment, compression and injection of gas into the transport pipeline are carried out.

A considerable experience has been accumulated that has no analogues in Russia, when working with low-pressure associated petroleum gas (from -0.05 MPa g). More than 70 of our units perform gathering and pumping of low-pressure APG at the following facilities of the oil and gas production complex:

- oil processing and pumping shops;

- oil verification departments;

- booster pumping stations;

- oil treatment units;

- central production facilities;

- terminal separation units;

- main transfer pumping stations;

- preliminary water removal units;

- complex gas treatment plants.

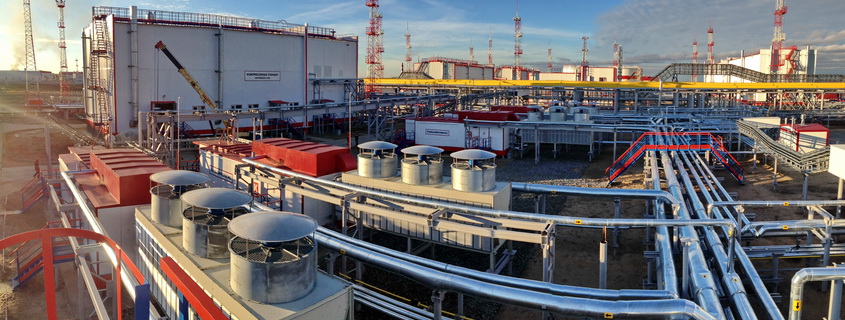

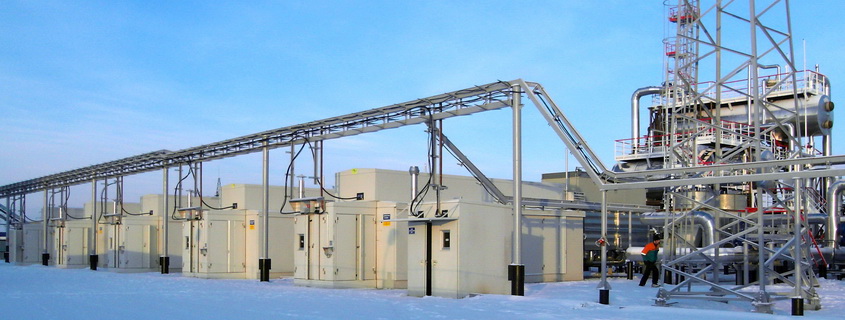

EXAMPLE OF PROJECT IMPLEMENTATION

Pyakyakhinskoye oil and gas condensate field of LLC LUKOIL-Western Siberia is equipped with a petroleum gas compressor station for APG gathering and transportation. There are 9 compressor units (CU) of various types and purposes that are supplied by the company ENERGAS:

- low pressure compressor unit. CU with capacity of 101 ... 2 160 m3 / h is pumping APG from the second stage of oil separation of OTU and gas from terminal separation unit;

- 4 block-modular compressor units for compression of associated gas coming from the first stage of oil separation. Capacity of each CU is 16 180 m3 / h;

- booster compressor unit of screw type. Gas flow rate is 4,660 ... 18,025 m3 / h. The functional of this CU is compression of gas from the condensate deethanization unit;

- 3 reciprocating compressor units with a capacity of 34 240 m3 / h. CU on the basis of reciprocating four-row single-stage compressors compress petroleum gas from facilities of the field up to 11 MPa for subsequent transportation to GPF.

The equipment is designed taking into account extreme operating conditions (minimum air temperature - minus 56 ° С, temperature of the coldest five-day period - minus 46 ° С). Operating mode is automatic, continuous. To measure APG flow rate, each CU is additionally equipped with a gas metering unit.

All units, except reciprocating, are placed in separate block-boxes, equipped with life support systems (heating, ventilation, lighting) and security (fire detection, fire-fighting, gas detection). In accordance with the design, the reciprocating CUs are located in a separate fundamental structure.

The whole cycle of prelaunch works, including supervision, adjustment, individual testing and integrated testing in the structure of the petroleum gas compressor station, was carried out by specialists of LLC ServicENERGAS (group of companies ENERGAS).