Power centers for own needs of fields

Large oil and gas producing companies equip their fields with power centers for own needs on the basis of gas turbine power plants or GTU-CHPP. The fuel for the power centers is, as a rule, associated petroleum gas.

Projects are carried out with the purpose of development of industrial activity in the fields and allow to accomplish a number of tasks:

- coverage of electrical loads in conditions of transmission constraints;

- generation of thermal power for various facilities of the fields;

- provision of process requirements for hot water for injection into seams;

- reduction of energy consumption costs;

- reducing the company's dependence on tariff policy in the electricity market;

- increase in the percentage of associated petroleum gas recovery.

ENERGAS has extensive experience in participating in these projects in part of gas treatment and gas feeding for generating equipment. In our asset there is supply the relevant units for 26 power centers built in recent years by LUKOIL, Surgutneftegas, Gazprom neft, Rosneft, and others.

To date as a part of power centers of fields there are reliably operating about 90 units of various purposes and modifications which are integrated into the equipment complexes of ENERGAS of the following types:

- fuel gas booster compressor station;

- multi-module fuel gas treatment unit;

- fuel gas compressor unit;

- multifunctional gas treatment and gas supply system;

- fuel gas treatment system of hangar (shop) type.

EXAMPLE OF THE PROJECT IMPLEMENTATION

At the Usinsk oil field there is operates power centers for own needs of LLC LUKOIL-Komi based on GTU-CHPP. Installed electric capacity of GTU-CHPP is 100 MW, thermal capacity is 120 Gcal / h.

Generating equipment comprises four power generating unit GTPP-25PA manufactured by the JSC UEC-Aviadvigatel each of which is based on a gas turbine unit GTE-25PA with capacity of 25 MW. For issuance of the thermal power at the GTU-CHPP there are mounted four waste-heat boilers.

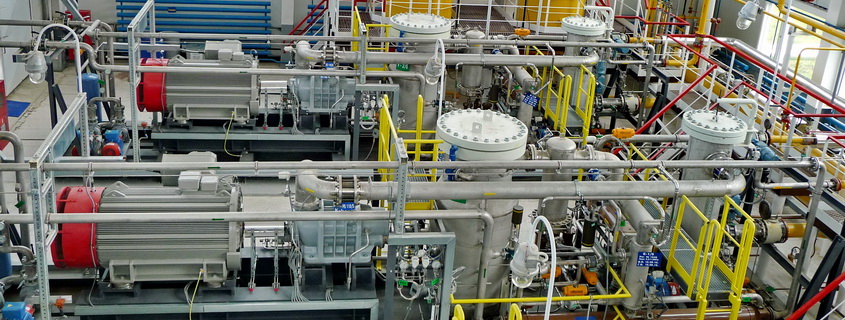

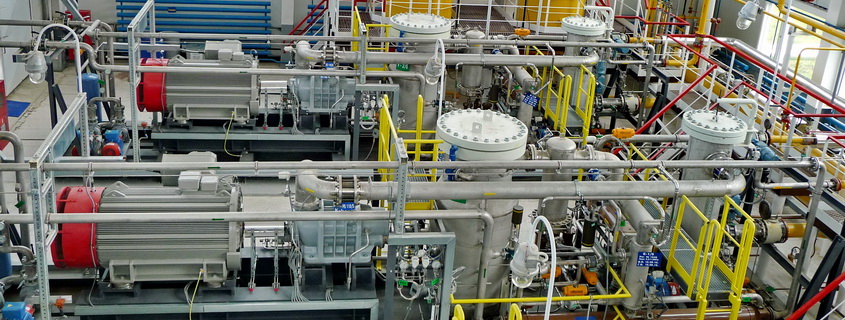

The main and reserve fuel for energy center is associated gas. The required gas parameters on purity, temperature, pressure and flow are provided by the multifunctional gas treatment system of ENERGAS, which is composed of booster compressor station and gas treatment unit.

Block-type gas treatment unit (BGTU) is a processing unit with maximum integration of the components on a single frame. Its main purpose is measurement of gas flow rate and gas filtration. BGTU is equipped with bilinear gas metering station, separator-slugcatcher and filtration module. The degree of gas purification is 100% for liquid fraction and 99.8% for solids of size larger than 10 microns.

Additional functionality – fuel treatment for the boiler of own needs. For this purpose BGTU is equipped with gas heating system and pressure reduction system. Capacity of unit is 2,260…21,684 kg/h (2,430…24,059 m3/h).

BGTU is located at an open site (inside easy-to-assemble enclosure); it is equipped with all necessary engineering systems. Operation mode is automatic. After pretreatment, the main gas flow is fed to the booster compressor station (BCS).

BCS compress gas up to operating pressure in the range of 4.5…5 MPa and feed it to the turbines of GTU-CHPP. It consists of three compressor units (CU) of screw type. Each CU has a capacity of 21,447 kg/h (23,794 m3/h) and it is designed for 100% loading of the total amount of fuel supplied to the power generating units. Gas flow rate is adjusted by means of the two-tier capacity regulation system.

BCS is completely automated. Individual ACS of units are integrated into the group system of automated management and control, which coordinates operation of these CU as a part of the compressor station and connected with the upper level of APCS of energy center.

Units are placed in separate block-modules equipped with life support systems and safety systems. According to customer requirements, at all CUs additionally there are installed gas dehydration systems and dew-point measurement systems with devices for sampling.

Gas treatment system is developed on special project. Inside CU and BGTU there is provided open space for easy and comfortable access to all assemblies and components what allows possibility for year-round quality performing of service activities (maintenance, spare parts and consumables replacement, overhaul, upgrade).

The phased commissioning of the multifunctional system, including erection supervision, start-up, individual testing, operability check as a part of GTU-CHPP, was performed by the engineers of LLC ServicENERGAS (ENERGAS Group).

Projects are carried out with the purpose of development of industrial activity in the fields and allow to accomplish a number of tasks:

- coverage of electrical loads in conditions of transmission constraints;

- generation of thermal power for various facilities of the fields;

- provision of process requirements for hot water for injection into seams;

- reduction of energy consumption costs;

- reducing the company's dependence on tariff policy in the electricity market;

- increase in the percentage of associated petroleum gas recovery.

ENERGAS has extensive experience in participating in these projects in part of gas treatment and gas feeding for generating equipment. In our asset there is supply the relevant units for 26 power centers built in recent years by LUKOIL, Surgutneftegas, Gazprom neft, Rosneft, and others.

To date as a part of power centers of fields there are reliably operating about 90 units of various purposes and modifications which are integrated into the equipment complexes of ENERGAS of the following types:

- fuel gas booster compressor station;

- multi-module fuel gas treatment unit;

- fuel gas compressor unit;

- multifunctional gas treatment and gas supply system;

- fuel gas treatment system of hangar (shop) type.

EXAMPLE OF THE PROJECT IMPLEMENTATION

At the Usinsk oil field there is operates power centers for own needs of LLC LUKOIL-Komi based on GTU-CHPP. Installed electric capacity of GTU-CHPP is 100 MW, thermal capacity is 120 Gcal / h.

Generating equipment comprises four power generating unit GTPP-25PA manufactured by the JSC UEC-Aviadvigatel each of which is based on a gas turbine unit GTE-25PA with capacity of 25 MW. For issuance of the thermal power at the GTU-CHPP there are mounted four waste-heat boilers.

The main and reserve fuel for energy center is associated gas. The required gas parameters on purity, temperature, pressure and flow are provided by the multifunctional gas treatment system of ENERGAS, which is composed of booster compressor station and gas treatment unit.

Block-type gas treatment unit (BGTU) is a processing unit with maximum integration of the components on a single frame. Its main purpose is measurement of gas flow rate and gas filtration. BGTU is equipped with bilinear gas metering station, separator-slugcatcher and filtration module. The degree of gas purification is 100% for liquid fraction and 99.8% for solids of size larger than 10 microns.

Additional functionality – fuel treatment for the boiler of own needs. For this purpose BGTU is equipped with gas heating system and pressure reduction system. Capacity of unit is 2,260…21,684 kg/h (2,430…24,059 m3/h).

BGTU is located at an open site (inside easy-to-assemble enclosure); it is equipped with all necessary engineering systems. Operation mode is automatic. After pretreatment, the main gas flow is fed to the booster compressor station (BCS).

BCS compress gas up to operating pressure in the range of 4.5…5 MPa and feed it to the turbines of GTU-CHPP. It consists of three compressor units (CU) of screw type. Each CU has a capacity of 21,447 kg/h (23,794 m3/h) and it is designed for 100% loading of the total amount of fuel supplied to the power generating units. Gas flow rate is adjusted by means of the two-tier capacity regulation system.

BCS is completely automated. Individual ACS of units are integrated into the group system of automated management and control, which coordinates operation of these CU as a part of the compressor station and connected with the upper level of APCS of energy center.

Units are placed in separate block-modules equipped with life support systems and safety systems. According to customer requirements, at all CUs additionally there are installed gas dehydration systems and dew-point measurement systems with devices for sampling.

Gas treatment system is developed on special project. Inside CU and BGTU there is provided open space for easy and comfortable access to all assemblies and components what allows possibility for year-round quality performing of service activities (maintenance, spare parts and consumables replacement, overhaul, upgrade).

The phased commissioning of the multifunctional system, including erection supervision, start-up, individual testing, operability check as a part of GTU-CHPP, was performed by the engineers of LLC ServicENERGAS (ENERGAS Group).