Training centers for technical specialists

A vivid example of the creation of such facilities is Polytechnic training center of OJSC "Surgutneftegas", which located at the Western-Surgut field (Khanty-Mansi Autonomous Area - Yugra).

The Center has been operating since 2016. Here you can obtain fundamental knowledge or improve your qualification in 349 professions. Every day the Center is ready to receive up to 500 students from among the company's employees. Today it can be stated that the Polytechnic training center of "Surgutneftegas" has no analogues not only in our country, but also in the world.

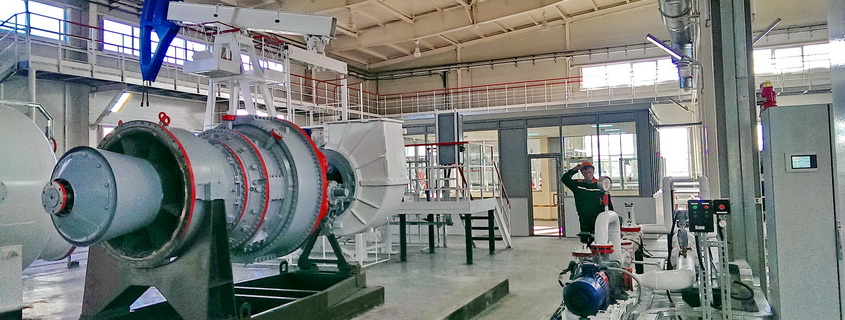

The Center is equipped with modern simulators, computer classes and laboratories. Here at the special ground there are installed training analogs of modern equipment operating in the fields of the company.

In the field of training of technical specialists, the power plant of the National Research University "MPEI" also attracts attention. MPEI CHPP is a unique facility that not only provides the energy needs of the University and the Lefortovo district of Moscow, but also makes a significant contribution to the scientific and educational potential of MPEI.

The plant is the site for the practical training of students of heat engineering, power engineering, electrical engineering specialties and perform research work in experimental-industrial conditions.

The skills and experience of ENERGAS engineers, as well as the capabilities of our equipment, allow the company to participate in such projects as a supplier of gas treatment units.

EXAMPLE OF THE PROJECT IMPLEMENTATION

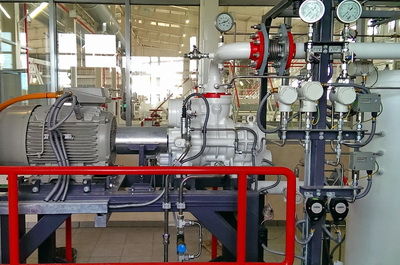

As a part of the training ground of Polytechnic training center of OJSC "Surgutneftegas" there is operates a compressor unit of the company ENERGAS made on the basis of a screw oil-filled compressor. This unit-simulator compresses air (up to 0.6 MPa) for training demonstration of technological processes at the gathering and pipeline transportation of gas.

Compressor unit (CU) is used when training of specialists of the appropriate profile. Capacity of CU varies in the range of 0...300 m3 / h and is adjusted by a two-tier regulation system (bypass line and spool regulation).

At CU inlet there is installed air treatment system – high efficiency separator similar to inlet scrubbers for gas filtering which are built-in in compressor units operating at facilities of the "Surgutneftegas".

The unit is fully automated. The control system implements preparation for start, start-up, shutdown and maintaining the optimum operating mode of the unit; it controls process parameters; it provides automatic protection and alarm system; it handles the parameters of the workflow and emergency events with the issuance of information on the standard protocol of exchange.

The whole set of works on commissioning of the unit-simulator has been performed by the service engineers of the company ENERGAS.